Are You Getting the Most Out of Your Coil Cut To Length Line

2025-11-21

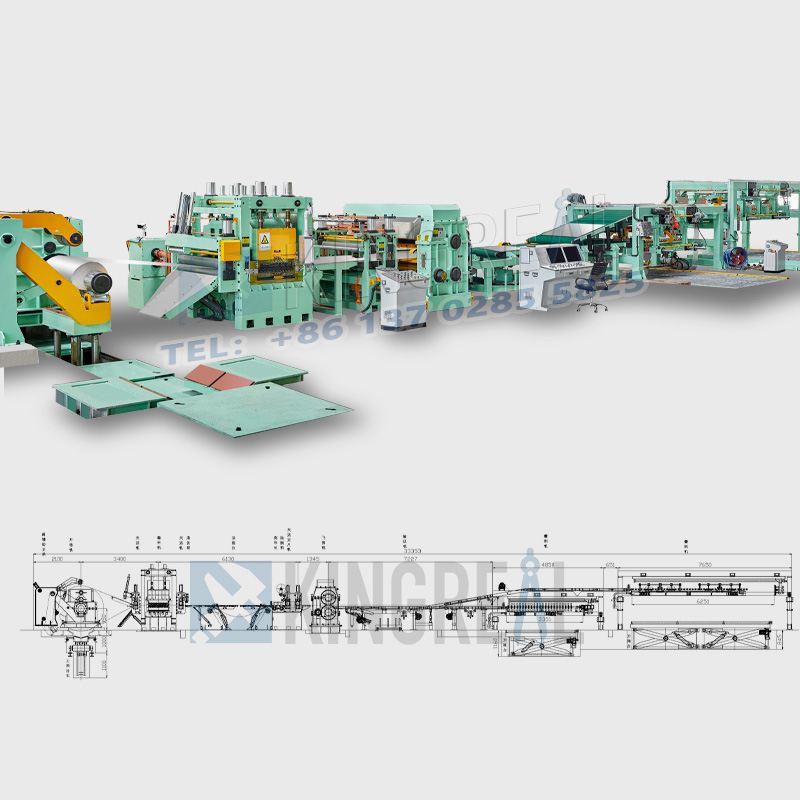

If you're questioning whether your current coil processing is operating at its peak potential, you're likely leaving efficiency and profit on the table. Maximizing your output requires a machine that combines robust engineering with precision control. This is where the KINGREAL Coil Cut To Length Machine sets a new industry standard, designed to transform your raw material into accurately blanked sheets with unparalleled consistency and minimal waste.

Our KINGREAL line is engineered for durability and high performance. We focus on key parameters that directly impact your bottom line.

-

High-Speed Operation: Achieve cycle times that dramatically increase your throughput.

-

Unmatched Precision: An advanced servo-driven system guarantees cut-length tolerances of ±0.005 inches (±0.13mm), sheet after sheet.

-

Material Versatility: Process a wide range of materials including mild steel, stainless steel, aluminum, and copper coils.

-

User-Centric Control: An intuitive PLC and HMI touchscreen interface allows for quick job changeovers and minimal operator training.

Key Technical Specifications:

| Feature | Specification |

|---|---|

| Max Coil Weight | 10 Tons |

| Max Line Speed | 60 m/min |

| Material Thickness | 0.3mm - 6.0mm |

| Cutting Tolerance | ±0.005 inches (±0.13mm) |

| Control System | PLC with HMI Touchscreen |

Coil Cut To Length Machine FAQ

What is the typical maintenance schedule for a KINGREAL Coil Cut To Length Machine?

Regular maintenance is straightforward. We recommend daily visual inspections and lubrication checks, with a more comprehensive preventive maintenance service scheduled every 500 operating hours or quarterly to ensure long-term reliability and performance.

Can your machine handle different material types and thicknesses without major changeover?

Yes. The KINGREAL Coil Cut To Length Machine is built for flexibility. The system can be quickly adjusted for different material types and thicknesses via the HMI screen, with physical changeovers of rollers and straighteners accomplished in minimal time, supporting just-in-time production schedules.

What kind of after-sales support and training does KINGREAL provide?

We provide comprehensive support, including on-site installation and commissioning by our expert engineers, detailed operator training, and a readily available inventory of spare parts. Our global service network ensures you receive prompt technical assistance whenever needed.

Stop settling for less than optimal performance from your production line. KINGREAL is committed to providing the machinery and support that empower your business to lead. To discover how our Coil Cut To Length Machine can be tailored to your specific needs and to request a detailed quotation, contact us today for a personalized consultation.