Can a Core Shooter Machine Improve My Foundry's Productivity

2025-12-08

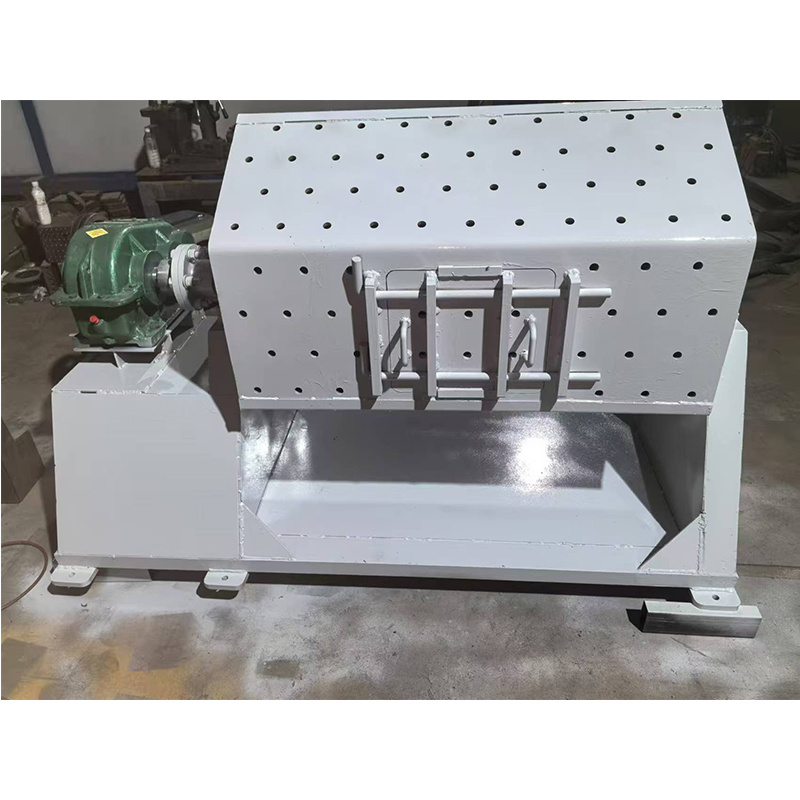

In the competitive world of metal casting, maximizing output and consistency is paramount. Foundries constantly seek technologies that streamline core production, a critical step that directly impacts final casting quality and throughput. This is where investing in a high-performance Core Shooter Machine becomes a strategic decision. At Yueli, we engineer advanced Core Shooter Machine solutions designed not just to automate but to revolutionize your core room operations, delivering tangible gains in productivity, precision, and profitability.

A Yueli Core Shooter Machine enhances productivity through unmatched reliability, precision, and speed. By automating the sand blowing and curing process, it eliminates manual inconsistencies, drastically reduces scrap rates, and enables faster cycle times. This allows your foundry to produce more high-quality cores per shift, meet tighter deadlines, and optimize labor allocation.

Key Features of a Yueli Core Shooter Machine:

Our machines are built for industrial endurance and precision. Here are some core parameters that set Yueli apart:

-

High-Pressure Blowing System: Ensures dense, uniform sand packing into complex core boxes for superior dimensional accuracy.

-

PLC Control with Touchscreen Interface: Allows for easy recipe storage, repeatable processes, and minimal operator training.

-

Robust Construction: Featuring hardened steel components for longevity in demanding foundry environments.

-

Energy-Efficient Design: Incorporates regenerative systems to reduce compressed air and energy consumption.

Model Comparison Table:

| Model | Max Core Box Size (mm) | Shot Capacity (kg) | Typical Cycle Time | Ideal For |

|---|---|---|---|---|

| Yueli CSM-800 | 800 x 800 | 15 | 25-40 seconds | High-mix, medium-volume production |

| Yueli CSM-1200 | 1200 x 1200 | 30 | 35-50 seconds | Large, complex cores for automotive/industrial castings |

Core Shooter Machine FAQ:

Q: How does a Core Shooter Machine improve core quality compared to manual methods?

A: It applies consistent, high-pressure sand blowing, which eliminates voids and ensures uniform density throughout the core. This repeatable precision minimizes casting defects like metal penetration or dimensional inaccuracies, leading to higher yield and less rework.

Q: What is the typical return on investment (ROI) for a Yueli machine?

A: ROI depends on your current volume and scrap rates, but customers typically see a payback period of 12-24 months. Savings come from reduced labor costs, lower scrap and rework, increased output, and consistent material usage.

Q: Can the machine handle different sand and binder types?

A: Yes. Yueli Core Shooter Machines are highly versatile. They can be configured for various cold box processes (amine, SO₂), no-bake sands, and other resin systems, allowing you to adapt to different production needs without major retooling.

Upgrading your core production is the most effective step to boost overall foundry productivity. A reliable Core Shooter Machine from Yueli provides the technological edge to produce more, waste less, and profit more. Our team is ready to analyze your specific operation and recommend the perfect model to achieve your goals.

Contact us today for a detailed consultation and a personalized productivity assessment. Let Yueli be your partner in powering your foundry's future.