How Can a Blister Sheet Machine Boost Your Production Line Efficiency

2025-11-27

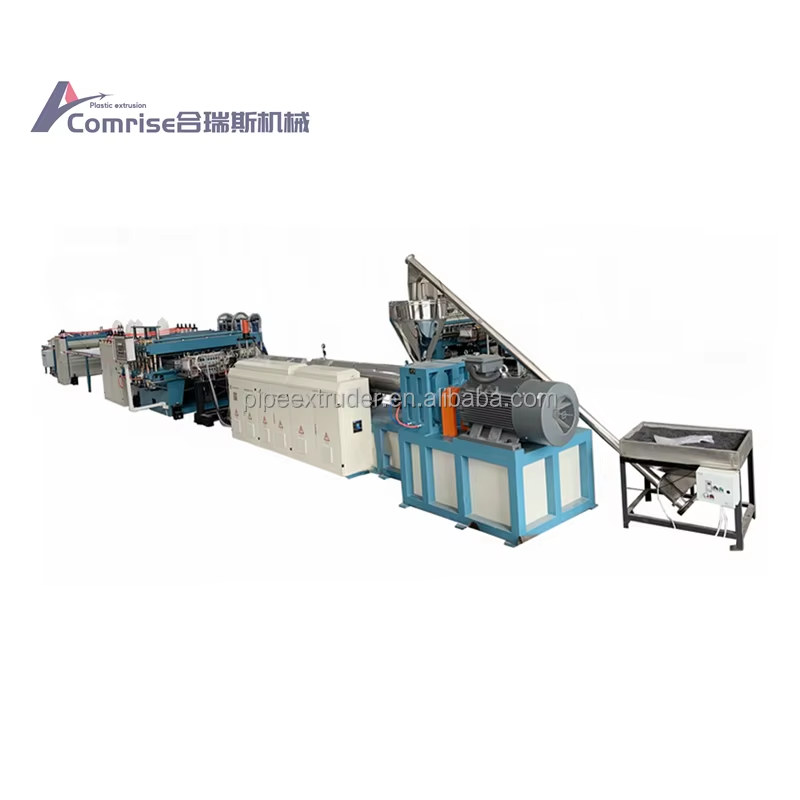

In today's competitive packaging landscape, maximizing output while minimizing downtime is paramount. A high-performance Blister Sheet Machine from Comrise is engineered to be a cornerstone of your operational success. But how exactly does it translate into measurable gains for your production line efficiency? This article breaks down the key features and benefits that set our equipment apart.

The engineering behind a Comrise Blister Sheet Machine focuses on three core areas: speed, precision, and reliability. By optimizing these elements, we deliver a machine that not only meets but exceeds modern production demands.

Key Parameters that Drive Efficiency:

-

High-Speed Thermoforming: Our machines operate at cycles significantly faster than industry standards, dramatically increasing your output per shift.

-

Precision Forming and Sealing: Advanced PLC controls ensure consistent cavity depth and hermetic seals, virtually eliminating product waste and rejected batches.

-

Quick-Change Tooling: Reduce changeover time from hours to minutes with our patented quick-change system, allowing for incredible flexibility in production scheduling.

-

Integrated Quality Control: On-line vision inspection systems can be integrated to automatically detect and reject faults, ensuring only perfect products move down the line.

The following table summarizes the direct impact of these features on your production line:

| Feature | Direct Impact on Production Efficiency |

|---|---|

| High-Speed Thermoforming | Increases units produced per hour, maximizing asset utilization. |

| Precision Sealing | Reduces material and product waste, lowering cost per unit. |

| Quick-Change Tooling | Minimizes downtime between production runs, boosting overall equipment effectiveness (OEE). |

| Automated Quality Control | Reduces manual inspection needs and prevents costly recalls. |

Blister Sheet Machine FAQ

What materials can the Comrise Blister Sheet Machine process?

Our Blister Sheet Machine is highly versatile and compatible with a wide range of thermoplastic materials, including PVC, PET, PP, and Aclar. This allows you to meet various product protection requirements, from moisture-sensitive pharmaceuticals to robust consumer goods.

How user-friendly is the operating interface?

The Comrise machine features an intuitive, fully graphical HMI (Human-Machine Interface). This touchscreen panel simplifies operation, reduces the training curve for new operators, and provides clear diagnostics for rapid troubleshooting, empowering your team to manage the line effectively.

What kind of maintenance and support can we expect?

We provide a comprehensive service package with every Blister Sheet Machine. This includes detailed maintenance schedules, remote diagnostic support, and readily available spare parts. Our global technical support network ensures that expert help is always available to keep your production running smoothly.

Investing in a Comrise Blister Sheet Machine is an investment in a more streamlined, profitable, and resilient production future. Our machines are built to deliver consistent performance day in and day out, transforming your packaging line into a key competitive advantage.

Contact us today to schedule a personalized consultation and see how our solutions can be tailored to your specific operational goals. Let's boost your efficiency together.