How Can a Cap Threader Improve Your Manufacturing Efficiency?

2025-09-15

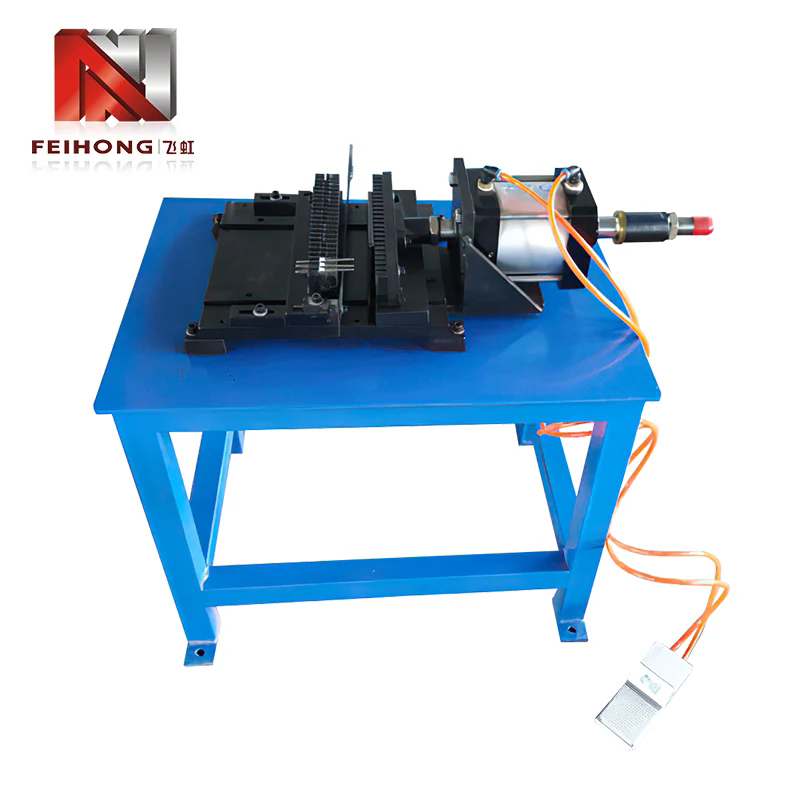

In the fast-paced world of industrial manufacturing, every second counts. Equipment that can streamline processes, reduce errors, and improve production speed is invaluable. One such device that has increasingly gained attention is the Cap Threader. Designed for precision and reliability, a Cap Threader ensures that caps are threaded onto bottles or containers efficiently and consistently, significantly reducing operational downtime.

At its core, a Cap Threader is engineered to automate the threading process. Unlike manual capping methods that are labor-intensive and prone to inconsistencies, Cap Threaders employ mechanical precision to ensure every cap fits perfectly, maintaining product integrity and enhancing consumer satisfaction.

Key Features and Advantages

The primary advantages of using a Cap Threader include:

-

Speed and Efficiency: Cap Threaders can handle high-volume operations with minimal intervention, allowing manufacturers to meet tight production schedules.

-

Precision and Consistency: By maintaining uniform torque and alignment, Cap Threaders prevent over-tightening or under-tightening, reducing product wastage.

-

Adaptability: Many models are compatible with a variety of bottle shapes, cap types, and thread sizes, making them versatile tools for multiple production lines.

-

Safety and Ergonomics: Automated threading reduces the need for repetitive manual labor, minimizing workplace injuries and improving operator comfort.

How Cap Threaders Transform Production Lines

Manufacturing lines that integrate Cap Threaders experience tangible improvements in workflow. For instance, bottling plants often deal with diverse product sizes and cap designs. A well-designed Cap Threader can adapt quickly without significant downtime, ensuring uninterrupted production. Furthermore, by minimizing the human factor in capping, these machines reduce the risk of contamination, maintaining high product quality standards essential for industries such as pharmaceuticals, food and beverages, and cosmetics.

What Are the Technical Specifications of a High-Performance Cap Threader?

To choose the right Cap Threader for your operation, it’s essential to understand its technical specifications. A comprehensive grasp of these details ensures that the machine aligns perfectly with your production requirements. Below is a table summarizing the primary specifications for a typical high-performance Cap Threader:

| Specification | Description |

|---|---|

| Model Name | CT-500X |

| Threading Speed | 30-120 caps per minute, adjustable |

| Cap Diameter Range | 20mm – 100mm |

| Bottle Height Compatibility | 50mm – 350mm |

| Torque Control | 0.5 – 5 Nm, programmable for different cap materials |

| Material Construction | Stainless steel frame, corrosion-resistant components |

| Power Supply | 220V/50Hz single-phase or 380V/3-phase, depending on model |

| Dimensions | 1200mm x 800mm x 1500mm |

| Weight | 250kg – 350kg |

| Control System | PLC touchscreen interface for precise operation and monitoring |

| Safety Features | Emergency stop, protective covers, and overload protection |

These specifications highlight the machine’s adaptability and robustness. Modern Cap Threaders are engineered to meet the most demanding production environments while ensuring long-term durability.

Why Should Manufacturers Invest in a Cap Threader?

Investing in a Cap Threader is not merely a purchase of machinery; it is a strategic decision that enhances operational efficiency, product quality, and overall profitability.

1. Reducing Operational Costs

Manual capping processes often require multiple operators and are prone to errors, leading to product loss or rework. By automating this step, manufacturers can significantly reduce labor costs, minimize wastage, and increase output per shift.

2. Enhancing Product Quality

Consistent torque application and precise cap alignment ensure that the product maintains its intended shelf life and safety standards. This is especially crucial for sectors like pharmaceuticals and beverages, where product integrity is paramount.

3. Supporting Scalability

A Cap Threader allows businesses to scale production effortlessly. Whether you are introducing a new product line or increasing batch sizes, a Cap Threader can handle varied production volumes without sacrificing speed or accuracy.

4. Minimizing Downtime

High-quality Cap Threaders are designed for reliability. Their modular design allows for easy maintenance, while real-time monitoring and PLC controls can prevent unexpected breakdowns, keeping the production line running smoothly.

Common Questions About Cap Threaders

Q1: How do I adjust the Cap Threader for different cap sizes?

A1: Most modern Cap Threaders come with adjustable guides and torque settings. By consulting the machine’s PLC interface, operators can select the cap diameter and threading torque, allowing the device to automatically adjust its alignment and speed to ensure consistent capping across different bottle sizes.

Q2: Can a Cap Threader handle both plastic and metal caps?

A2: Yes, high-performance Cap Threaders are designed to work with a wide range of cap materials, including plastic, aluminum, and composite types. The machine’s torque control ensures that delicate caps are not damaged, while stronger caps receive sufficient tightening to secure the container properly.

Integrating Cap Threaders Into Modern Manufacturing Workflows

Modern manufacturing demands flexibility and efficiency. Cap Threaders are no longer isolated machines; they are part of an interconnected production ecosystem. Integration with conveyor systems, sensors, and automated packaging lines ensures a seamless workflow, enabling manufacturers to optimize their entire production process.

Key Integration Benefits

-

Data Monitoring and Analytics: Advanced Cap Threaders provide real-time data on production speed, cap alignment accuracy, and torque application. This data can be used to identify bottlenecks, predict maintenance needs, and improve overall line efficiency.

-

Reduced Human Error: Automation minimizes mistakes that can occur during manual capping, such as inconsistent torque or misaligned threads.

-

Enhanced Safety Compliance: Integrating safety sensors and emergency stops ensures that operators are protected while maintaining continuous production flow.

-

Customizable for Specific Industries: Whether for pharmaceutical bottles, cosmetic containers, or beverage products, Cap Threaders can be tailored to meet precise industry standards.

By incorporating Cap Threaders into production lines, companies can achieve higher throughput, maintain quality control, and reduce operational strain, making it a vital investment for long-term competitiveness.

The Cap Threader is a transformative tool in modern manufacturing. It combines speed, precision, and adaptability to improve productivity, maintain consistent quality, and minimize operational costs. For businesses looking to stay competitive, integrating a high-performance Cap Threader into their workflow is not just a convenience—it is a necessity.

At Feihong, we specialize in providing advanced Cap Threaders designed to meet the diverse needs of manufacturers worldwide. Our machines offer precision, durability, and seamless integration capabilities. To explore how our Cap Threaders can enhance your production line, contact us today for personalized consultation and support.