How Can Skirt Rubber Improve Industrial Efficiency?

2025-12-30

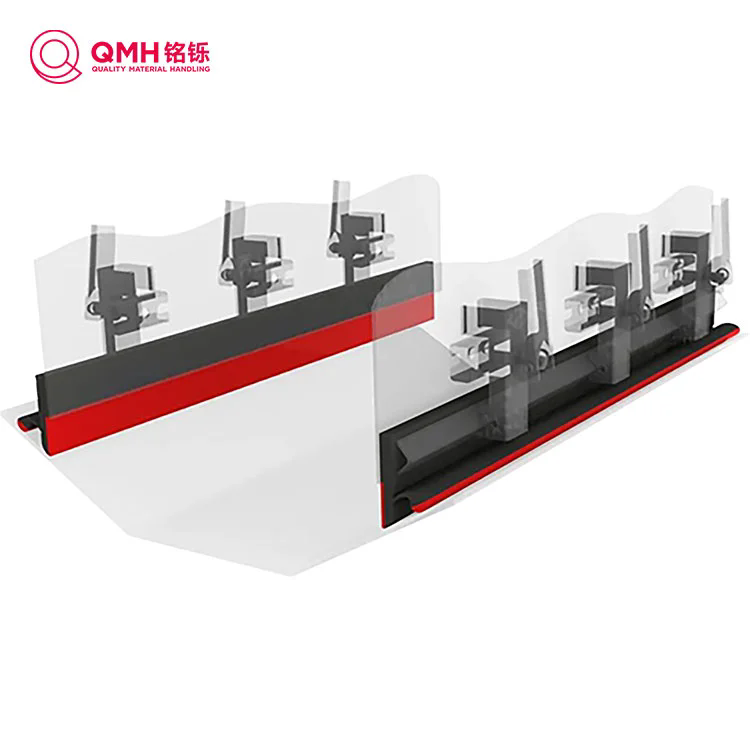

Introduction to Skirt Rubber

Skirt Rubber is a specialized industrial material used primarily in conveyor systems and bulk material handling. Its primary function is to provide sealing, reduce material spillage, and protect machinery components from wear. This article explores the applications, specifications, and common inquiries regarding Skirt Rubber, aiming to provide a comprehensive reference for engineers, procurement managers, and industrial technicians.

The main focus of this article is to explain the technical properties, uses, and operational advantages of Skirt Rubber while addressing frequently asked questions to help businesses select the right type for their applications.

Product Specifications

Skirt Rubber is available in a variety of grades, sizes, and hardness levels depending on operational requirements. Below is a detailed specification table illustrating the primary technical parameters:

| Parameter | Description | Typical Range |

|---|---|---|

| Material Composition | Natural and synthetic rubber blends designed for wear resistance | NR/SBR/EPDM mixtures |

| Hardness (Shore A) | Resistance to indentation for durability under mechanical stress | 60-90 |

| Temperature Range | Operational temperature resistance for industrial environments | -30°C to +80°C |

| Tensile Strength | Maximum stress material can withstand while being stretched | 15-25 MPa |

| Elongation at Break | Measure of flexibility and stretch before rupture | 300%-600% |

| Thickness Options | Variety of thicknesses for different conveyor types | 5mm – 20mm |

Applications and Industrial Use

Skirt Rubber is commonly applied in industries such as mining, cement, chemical, and bulk material handling. Its primary functions include:

- Reducing spillage in conveyor systems

- Minimizing equipment wear and tear

- Providing noise reduction in industrial processes

- Enhancing overall operational efficiency

How does Skirt Rubber improve conveyor performance? By forming a tight seal between the conveyor belt and the skirt board, it prevents fine materials from escaping, thereby maintaining material flow and reducing maintenance frequency.

In addition, Skirt Rubber can be customized based on the type of material handled (abrasive, wet, or fine powder), operational speed, and environmental conditions. Choosing the correct hardness and thickness is critical to achieving maximum lifespan and operational reliability.

Common Questions About Skirt Rubber

A1: Selection should consider material type, conveyor speed, temperature range, hardness, and thickness. High abrasion areas require tougher rubber grades, while chemically sensitive materials may need EPDM or specialized blends.

A2: Lifespan depends on operational conditions. Under moderate use, high-quality Skirt Rubber can last 12–24 months. Frequent inspections and proper installation significantly extend service life.

A3: Yes, modular skirt rubber designs allow partial replacement without halting production. Split or segmented panels facilitate maintenance and minimize downtime.

A4: Proper installation requires aligning the skirt with the conveyor belt, ensuring uniform contact without gaps, and securing using mechanical fasteners or adhesives based on operational conditions.

A5: Used rubber should be recycled or disposed of according to local environmental regulations. Many industrial facilities partner with recycling firms to reduce landfill waste and reclaim rubber material.

Conclusion and Contact

Skirt Rubber remains a critical component in bulk material handling and industrial operations. Understanding its technical specifications, applications, and maintenance requirements ensures operational efficiency and longevity. Businesses can select appropriate Skirt Rubber grades to optimize performance and reduce downtime.

The brand QMH provides high-quality Skirt Rubber solutions with a focus on durability, precision, and customization to meet industrial demands. For further inquiries or to request a quote, contact us today to discuss your specific operational needs.