How Do Heat-Resistant Thick Board Machines Improve Production Efficiency?

2025-12-11

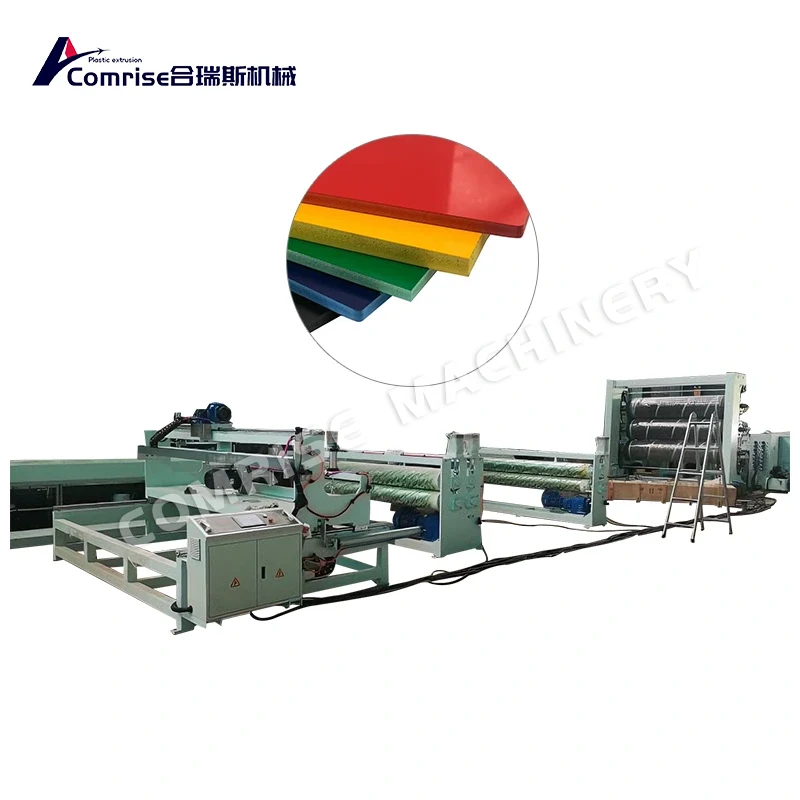

Production efficiency in plastic board manufacturing largely depends on the stability, precision, and throughput of the machinery. Heat-resistant thick board machines are designed to maintain optimal performance even under high-temperature conditions, which is critical for producing high-quality plastic board machine outputs consistently. In our factory, we have focused on enhancing the heat management system, mechanical durability, and automation controls to ensure every unit meets the rigorous standards required in industrial environments. Qingdao Comrise Machinery Co., Ltd. has implemented innovative engineering solutions that directly translate into improved productivity and reduced downtime.

How Does Temperature Control in Plastic Board Machines Affect Output Quality?

Temperature management is one of the most significant factors influencing both quality and efficiency. Heat-resistant thick board machines integrate advanced thermal control systems that maintain stable temperatures throughout the extrusion and shaping processes. Our team carefully calibrates these systems to ensure uniform heat distribution across the board, minimizing defects such as warping, bubbles, or uneven thickness. For customers using Plastic Board Machine units in high-volume operations, consistent temperature control reduces material waste and improves overall throughput.

In our factory, we also monitor heating element performance and insulation effectiveness to prevent energy loss. Qingdao Comrise Machinery Co., Ltd. emphasizes precision temperature control as a key driver for operational efficiency and reduced maintenance costs. Operators frequently note the difference in output quality when switching from standard boards to units equipped with our heat-resistant technology.

What Are the Mechanical Advantages That Improve Production Efficiency?

Mechanical stability and strength are essential for maintaining consistent output. Heat-resistant thick board machines are designed with reinforced frames, high-torque drives, and vibration-resistant components that allow the equipment to operate continuously without performance degradation. Our engineering team evaluates the entire drive system to balance speed, pressure, and board thickness tolerance. When customers integrate Plastic Board Machine units with reinforced mechanical designs, they experience fewer stoppages and a smoother production workflow.

The combination of mechanical precision and heat resistance ensures that our machines handle heavy loads without reducing efficiency. In our factory, we routinely perform stress tests on the moving parts to verify durability under extended operational cycles. Qingdao Comrise Machinery Co., Ltd. provides documentation for expected operational life, which helps manufacturers plan maintenance and replacement schedules effectively.

How Do Automation Features in Plastic Board Machines Enhance Throughput?

Automation is a critical factor in improving production efficiency. Our heat-resistant thick board machines incorporate automatic feeding, real-time thickness monitoring, and adaptive speed controls. These features allow operators to maintain a high output rate while ensuring product quality. By reducing manual intervention, our factory ensures consistency and reduces the chance of errors that could slow down production.

We have also developed integrated control panels that allow operators to monitor machine performance in real time. Qingdao Comrise Machinery Co., Ltd. emphasizes user-friendly interfaces so that adjustments can be made quickly without interrupting the production process. Customers often report that automated Plastic Board Machine units lead to a 20–30 percent increase in effective production time compared to conventional setups.

How Does Material Handling Impact Production Efficiency in Plastic Board Machines?

Efficient material handling directly contributes to overall throughput. Our machines feature enhanced feeding systems that maintain steady material flow even under high-temperature conditions. This reduces the likelihood of jams or uneven material distribution, which can slow production. In our factory, we calibrate feed rollers and conveyor systems to match the specific characteristics of the raw material being processed. Operators using Plastic Board Machine units notice smoother operation and consistent board quality across extended production runs.

Qingdao Comrise Machinery Co., Ltd. also emphasizes the importance of synchronized cooling systems to stabilize the final product dimensions. Efficient handling, combined with precise temperature management, ensures that each board meets design specifications, reducing the need for post-processing adjustments.

How Do Maintenance Practices Influence the Efficiency of Heat-Resistant Thick Board Machines?

Regular maintenance is essential to preserve production efficiency. Heat-resistant thick board machines require inspection of heating elements, rollers, and control systems. Our factory provides detailed maintenance schedules and operational guidelines for customers to follow. Performing preventive maintenance reduces unexpected downtime and ensures that Plastic Board Machine units maintain peak performance over time.

In addition, our team offers on-site training to help operators identify early signs of wear or potential failures. Qingdao Comrise Machinery Co., Ltd. believes that combining robust machine design with proactive maintenance practices maximizes production efficiency and extends the operational life of the equipment.

What Are the Key Performance Parameters for Heat-Resistant Thick Board Machines?

Understanding the key specifications helps manufacturers optimize machine operation. The table below provides a reference for commonly requested parameters:

| Parameter | Specification Range | Impact on Production | Notes |

| Max Operating Temperature | 250–300°C | Ensures stable extrusion | Prevents material degradation |

| Board Width | 800–2000 mm | Supports high-volume production | Adjustable based on line requirements |

| Extrusion Speed | 5–20 m/min | Controls throughput and quality | Optimized for material type |

| Roller Pressure | 50–150 kN | Maintains board thickness uniformity | Calibrated for heat resistance |

How Does Energy Efficiency Relate to Production Output?

Energy-efficient operation not only reduces costs but also stabilizes machine performance. Our heat-resistant thick board machines use advanced insulation and optimized heating circuits to minimize energy loss. Our factory also tests power consumption under different operating conditions to identify areas for improvement. When manufacturers use Plastic Board Machine units with optimized energy design, they observe more stable temperatures and reduced material waste, leading to higher effective production rates.

The second table summarizes energy and output metrics for different machine configurations.

| Machine Type | Energy Consumption (kWh) | Production Rate (Boards/Hour) | Efficiency Notes |

| Standard | 120 | 80–100 | Baseline efficiency for comparison |

| Enhanced Heat-Resistant | 105 | 100–130 | Higher throughput with lower energy |

| Fully Automated | 110 | 120–150 | Optimal balance of automation and energy use |

FAQ: How Do Heat-Resistant Thick Board Machines Improve Production Efficiency?

Q1: How does heat resistance contribute to continuous production?

Heat-resistant components allow the machine to maintain stable temperatures during extended runs, preventing warping and material degradation. This ensures consistent output and reduces interruptions caused by thermal fluctuations.

Q2: Why is automation important for throughput in Plastic Board Machine units?

Automation reduces manual intervention and maintains uniform board thickness. Features such as real-time monitoring and adaptive speed control help operators achieve higher output rates while maintaining quality.

Q3: What role does material handling play in efficiency?

Efficient feeding and synchronized cooling systems prevent jams and uneven boards. Proper handling ensures steady production flow and reduces defects, contributing to higher overall efficiency.

Conclusion

Heat-resistant thick board machines improve production efficiency by combining precise temperature control, mechanical stability, automation, and efficient material handling. Our factory integrates these features into Plastic Board Machine units to deliver reliable, high-quality output while minimizing energy consumption and downtime. Qingdao Comrise Machinery Co., Ltd. is committed to helping manufacturers optimize their production lines. For guidance on selecting the right equipment or improving your existing system, contact our technical team today to explore customized solutions that enhance efficiency and output.