How Does a Paper Tube Machine Work?

2025-09-01

In today’s rapidly evolving packaging industry, paper tube machines have become indispensable. From food packaging to industrial applications, paper tubes are everywhere — offering sustainability, durability, and cost efficiency. Businesses looking to optimize production are increasingly investing in advanced paper tube machines to meet the growing demand for eco-friendly packaging solutions.

What Is a Paper Tube Machine and Why It Matters

A paper tube machine is specialized industrial equipment designed to produce cylindrical tubes made from multiple layers of kraft paper or cardboard. These tubes are widely used in industries such as textiles, food and beverage, cosmetics, chemicals, and construction. With sustainability driving packaging innovation, paper tubes are replacing traditional plastic alternatives, and choosing the right machine can directly impact your production efficiency and product quality.

Key Applications of Paper Tube Machines

-

Packaging Industry: Producing tubes for food wraps, chips, biscuits, and cosmetic containers.

-

Textile Industry: Creating sturdy cores for fabric, yarn, and thread rolls.

-

Industrial Uses: Manufacturing cores for adhesive tapes, films, and plastic sheets.

-

Construction Sector: Producing concrete form tubes and protective sleeves.

-

Consumer Goods: Making eco-friendly mailing tubes, paper cans, and custom gift packaging.

As the global demand for sustainable packaging continues to grow, investing in a high-quality paper tube machine has become a strategic decision for manufacturers.

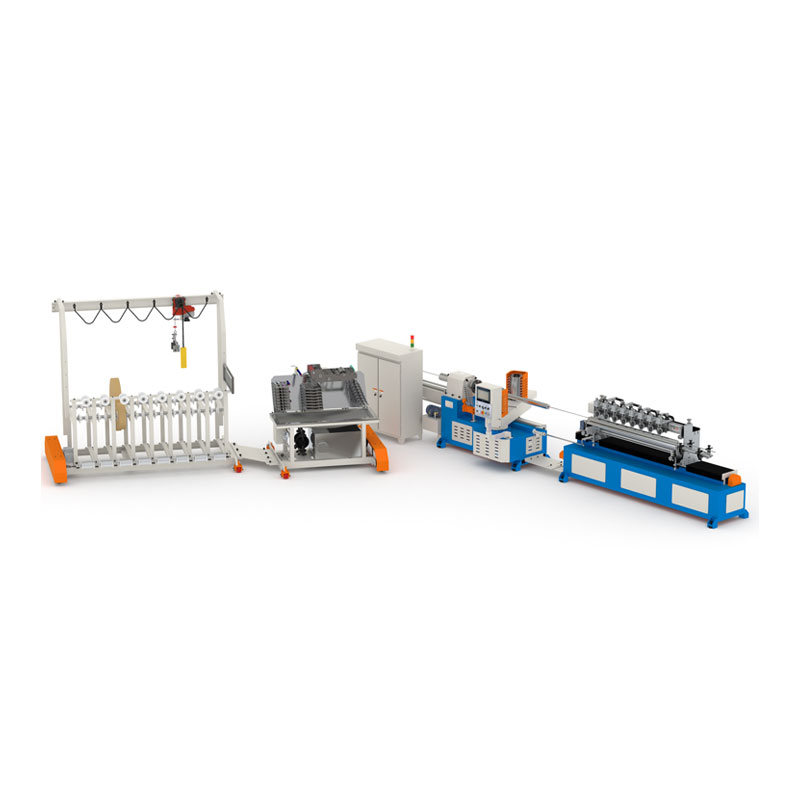

How Does a Paper Tube Machine Work?

Understanding the working principle of a paper tube machine is essential for choosing the right model. While machine types and automation levels may vary, most machines follow these core operational stages:

Paper Feeding

Multiple rolls of kraft paper or laminated paper are mounted on the machine’s unwind stands. The system automatically feeds the sheets into the forming section while maintaining precise tension control to prevent misalignment or wrinkles.

Gluing Process

An advanced adhesive application system uniformly coats each paper layer with eco-friendly glue. Depending on the product, hot melt or water-based adhesives are used to ensure strong bonding between layers.

Tube Winding & Forming

The coated paper layers are spirally or parallelly wound around a rotating mandrel, forming a cylindrical tube. The winding angle can be adjusted to meet specific strength and thickness requirements.

Precision Cutting

Once the continuous tube reaches the desired diameter and wall thickness, it is automatically cut into preset lengths using a servo-driven cutting system.

Drying & Finishing

Some machines integrate drying systems for faster adhesive curing, ensuring durability and uniform quality. Optional polishing, trimming, and edge-beveling units are available for high-end packaging applications.

Advantages of Modern Paper Tube Machines

| Feature | Benefit |

|---|---|

| High-speed production | Produces up to 50-200 tubes/min |

| Precision control | Ensures uniform thickness and diameter |

| Eco-friendly adhesives | Supports sustainable manufacturing |

| Automated tension control | Prevents paper breakage and waste |

| Integrated drying system | Reduces curing time for faster output |

| Flexible customization | Supports various diameters and lengths |

Investing in an advanced paper tube machine enhances production efficiency, reduces labor costs, and ensures consistent product quality, making it an essential asset for packaging manufacturers.

Choosing the Right Paper Tube Machine: Technical Specifications

When selecting a paper tube machine, understanding its specifications is crucial to match your production needs. Below is an example of technical specifications offered by NEW STAR’s automatic paper tube machines:

| Model | Paper Layers | Tube Diameter Range | Tube Thickness | Speed | Power |

|---|---|---|---|---|---|

| NS-PTM100 | 3–10 layers | 30–200 mm | 1–8 mm | 50–80 pcs/min | 7.5 kW |

| NS-PTM200 | 5–15 layers | 40–350 mm | 2–12 mm | 80–120 pcs/min | 11 kW |

| NS-PTM300 | 7–20 layers | 50–450 mm | 3–15 mm | 100–200 pcs/min | 15 kW |

Factors to Consider Before Buying

-

Production Volume – Match machine speed and capacity to your business scale.

-

Tube Size Range – Choose a model that supports your product’s required diameters and thicknesses.

-

Automation Level – Fully automatic machines reduce labor while maintaining high consistency.

-

Energy Efficiency – Select models with optimized power consumption and eco-friendly glue systems.

-

Maintenance & Support – Opt for brands that offer reliable after-sales service and easy spare parts replacement.

Paper Tube Machine FAQs

Q1: How do I choose between spiral-winding and parallel-winding paper tube machines?

A: Spiral-winding machines wrap paper layers diagonally, creating stronger tubes ideal for heavy-duty applications such as textile cores and concrete forms. Parallel-winding machines arrange paper layers straight, resulting in smooth, premium surfaces suitable for cosmetics, food, and gift packaging.

Q2: What maintenance is required for a paper tube machine?

A: Regular maintenance includes lubricating moving parts, checking adhesive nozzles, cleaning cutting blades, and inspecting paper tension systems. Preventive servicing every 3–6 months ensures optimal performance and prolongs machine lifespan.

As packaging trends shift towards sustainability, paper tube machines are now at the heart of eco-friendly manufacturing. Whether you need compact machines for small-batch production or high-speed models for industrial-scale operations, investing in reliable equipment ensures product quality, operational efficiency, and long-term profitability.

NEW STAR offers a full range of high-performance paper tube machines tailored to meet diverse manufacturing needs. With cutting-edge technology, precision engineering, and dedicated customer support, NEW STAR helps businesses worldwide streamline production and stay competitive.

Looking to enhance your packaging production? Contact us today to discuss your specific requirements and discover how NEW STAR’s solutions can accelerate your business growth.