How Does an AAC Cement Brick Making Machine Transform Modern Construction Efficiency?

2025-12-30

In today's construction industry, efficiency, sustainability, and consistent quality are no longer optional—they are decisive factors for competitiveness. An AAC Cement Brick Making Machine is specifically designed to meet these demands by producing Autoclaved Aerated Concrete (AAC) bricks that are lightweight, strong, and environmentally friendly. With rising labor costs and stricter building standards worldwide, manufacturers and contractors are increasingly turning to advanced AAC solutions to optimize production while reducing long-term costs. As a global leader in concrete block machinery, ZENITH Maschinenfabrik GmbH delivers proven technology that supports both industrial-scale production and strategic business growth.

What Is an AAC Cement Brick Making Machine?

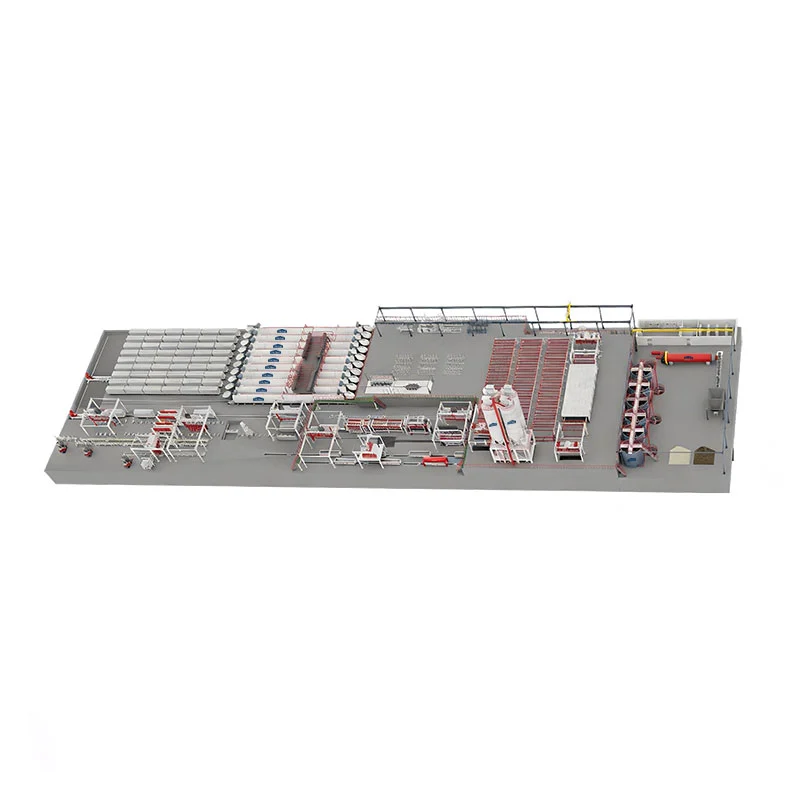

An AAC Cement Brick Making Machine is an integrated production system used to manufacture AAC blocks or bricks through a controlled process involving cement, lime, silica sand, water, and aluminum powder. After mixing and molding, the material undergoes pre-curing, cutting, and autoclaving, resulting in highly uniform and porous blocks.

Key Components

-

Raw material batching and mixing system

-

Molding and pre-curing unit

-

Cutting machine for precise dimensions

-

Autoclave for high-pressure steam curing

-

Automated handling and stacking system

Why AAC Cement Brick Making Machine vs Traditional Clay Brick Machines?

| Aspect | AAC Cement Brick Making Machine | Clay Brick Machine |

|---|---|---|

| Weight | Lightweight, porous structure | Heavy, dense |

| Thermal Insulation | Excellent | Limited |

| Production Automation | High | Medium |

| Environmental Impact | Low emissions, recyclable | High energy consumption |

| Construction Speed | Faster | Slower |

This comparison highlights why AAC technology has become the preferred choice for modern green buildings.

Core Functions and Practical Effects

Main Functions

-

Producing standardized AAC blocks with tight tolerances

-

Reducing raw material waste through automation

-

Supporting continuous, high-capacity production

Usage Effects

-

Lower transportation and structural load costs

-

Improved thermal and acoustic performance of buildings

-

Faster installation due to precise block sizing

Importance of AAC Cement Brick Making Machine in Construction

The importance of an AAC Cement Brick Making Machine lies in its ability to align construction with sustainability goals while maintaining economic efficiency. AAC bricks reduce energy consumption in buildings, comply with international green building standards, and offer long service life with minimal maintenance.

From a manufacturer's perspective, investing in a reliable system from ZENITH Maschinenfabrik GmbH ensures:

-

Stable production quality

-

Lower operational risk

-

Strong brand credibility in local and international markets

Why Choose ZENITH Maschinenfabrik GmbH?

With decades of engineering experience, ZENITH Maschinenfabrik GmbH integrates German precision, intelligent automation, and durable design into every AAC Cement Brick Making Machine. Our solutions are tailored to customer capacity requirements and regional standards, providing both technical reliability and long-term return on investment.

In conclusion, an AAC Cement Brick Making Machine is not just a piece of equipment—it is a strategic asset for companies aiming to lead in modern construction materials. If you are looking to upgrade your production line, reduce costs, and enhance product quality, ZENITH Maschinenfabrik GmbH is your trusted partner.

For customized solutions, technical consultation, or project planning, contact us today and take the next step toward efficient and sustainable brick production.