How is a Krah Pipe Machine Used in Producing HDPE Spiral Wound Pipes

2025-12-24

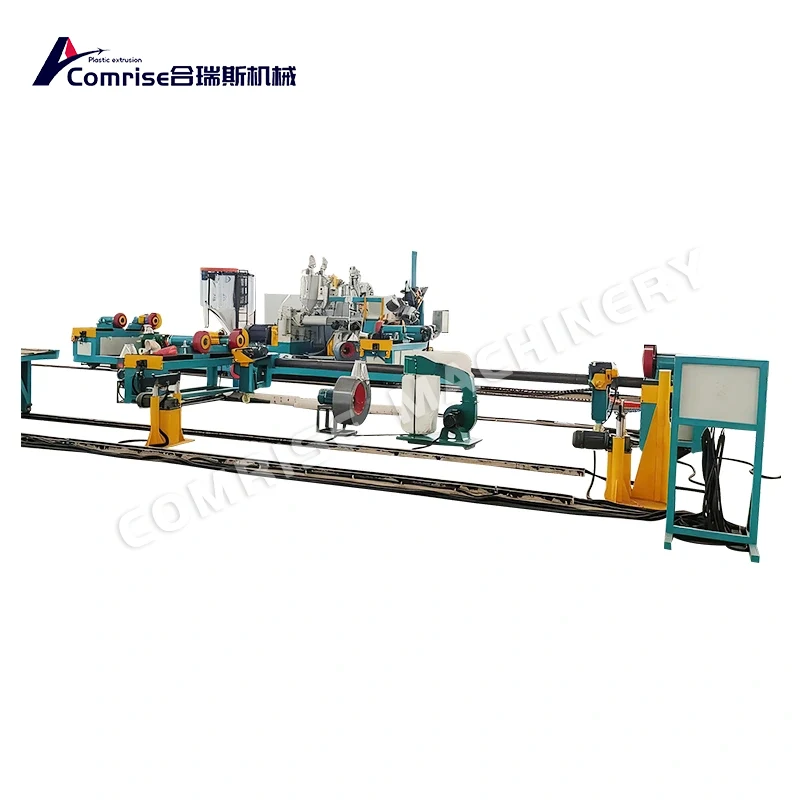

The production of large-diameter plastic pipes for critical infrastructure demands efficiency, structural integrity, and cost-effectiveness. This is precisely where the innovative Krah Pipe Machine excels. At Comrise, we leverage this advanced technology to manufacture superior HDPE spiral wound pipes, a cornerstone solution for modern drainage, sewerage, and culvert systems. This process transforms high-density polyethylene (HDPE) into robust, dimensionally stable pipes through a continuous, automated winding method, offering distinct advantages over traditional manufacturing.

The core operation of a Krah Pipe Machine involves a precise, multi-step extrusion and winding process:

-

Material Preparation & Extrusion: High-quality HDPE raw material is fed, melted, and extruded through a die head to form a continuous, molten profile.

-

Spiral Winding & Fusion: This profile is spirally wound onto a rotating mandrel. The key lies in the simultaneous fusion of the profile edges using controlled heat and pressure, creating a seamless, monolithic pipe wall structure.

-

Cooling & Calibration: The newly formed pipe section is cooled uniformly to stabilize its shape and dimensions.

-

Cutting & Handling: Once the desired length is achieved, the pipe is cleanly cut and prepared for handling, all in a continuous production cycle.

This method grants HDPE spiral wound pipes exceptional properties, as summarized in the table below:

| Property | Advantage | Benefit |

|---|---|---|

| Structural Strength | High ring stiffness (SN classes) | Withstands heavy loads and deep bury depths. |

| Leak-Free Joints | Seamless, monolithic structure from Krah Pipe Machine production. | Eliminates infiltration/exfiltration, protecting groundwater. |

| Corrosion Resistance | Inert nature of HDPE material. | Long service life (>100 years) in aggressive soil conditions. |

| Lightweight & Long Lengths | Efficient production and easy handling. | Reduces transportation and installation costs significantly. |

Krah Pipe Machine FAQ

Q: What is the maximum diameter a Krah Pipe Machine can produce?

A: The Krah Pipe Machine technology is renowned for its capability to produce very large diameters. While standard machines efficiently manufacture pipes from DN/ID 300mm up to DN/ID 3500mm, customized solutions from providers like Comrise can be engineered for even larger diameters to meet specific project requirements.

Q: How does the spiral winding process ensure pipe strength?

A: The strength is achieved through two key factors. First, the continuous, interlocked spiral winding creates a structurally optimal shape. Second, and most critically, the in-process thermal fusion of the profile edges creates a homogeneous, weld-strength bond across the entire pipe wall, making it as strong as a solid wall pipe without the material penalty.

Q: Can a Krah Pipe Machine use recycled HDPE material?

A: Yes, a significant advantage of this technology is its compatibility with co-extrusion. A Krah Pipe Machine can be equipped to process a layered wall structure, for instance, using a core layer of high-quality recycled HDPE sandwiched between inner and outer layers of virgin material. This allows Comrise to support sustainable production without compromising the pipe's performance or longevity.

Understanding the sophisticated engineering behind the Krah Pipe Machine reveals why it is the preferred method for manufacturing large-diameter HDPE spiral wound pipes. The result is a durable, reliable, and economical piping solution that stands the test of time and environmental challenge.

Ready to integrate this advanced piping technology into your next infrastructure project? Contact us at Comrise today for a detailed consultation and to discover how our expertise can provide the optimal solution for your specific needs.