Is Sustainability a Key Feature in Modern Intelligent Packaging Lines

2025-12-03

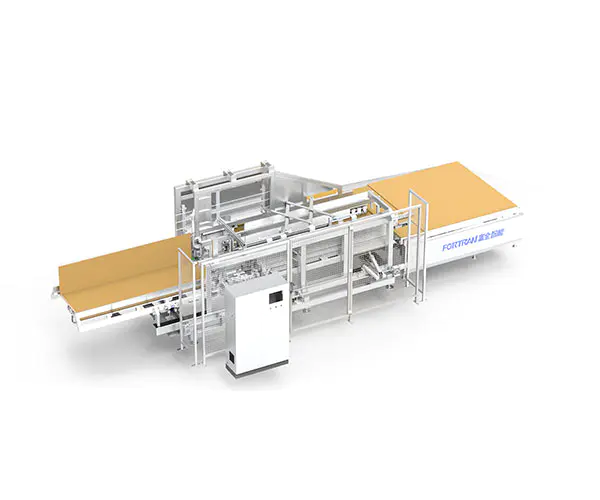

In today's manufacturing landscape, efficiency is no longer the sole benchmark for success. The pressing question is: Is sustainability a key feature in modern intelligent packaging lines? The answer is a definitive yes. Modern buyers and regulators demand eco-conscious production, making sustainability not just an added benefit but a core operational pillar. At Fortran, we engineer our Intelligent Packaging Line Series with this principle at its heart, proving that peak performance and environmental responsibility can be seamlessly integrated.

Our Fortran Intelligent Packaging Line Series is designed to minimize ecological impact at every stage:

-

Energy Efficiency: Utilizing advanced servo-driven motors and smart sleep modes, our lines reduce energy consumption by up to 30% compared to conventional systems.

-

Material Reduction & Optimization: Precision dosing and cutting technologies ensure minimal material waste. Our systems are compatible with a wide range of recycled and mono-materials.

-

Durability & Longevity: Built with premium components, the series ensures a longer lifecycle, reducing the frequency of machinery replacement and its associated carbon footprint.

-

Data-Driven Optimization: Integrated sensors provide real-time analytics on resource use, enabling continuous improvement in reducing waste and energy.

The following table outlines the key sustainable parameters of our flagship model, the Fortran EcoFlex 3000, part of our Intelligent Packaging Line Series:

| Feature | Parameter/Specification | Sustainable Benefit |

|---|---|---|

| Power System | High-efficiency servo motors with regenerative braking | Reduces energy consumption by ~30% |

| Material Waste | AI-guided precision cutting with tolerance < 0.5mm | Minimizes material overuse by up to 15% |

| Compatibility | Designed for PCR (Post-Consumer Recycled) content materials | Supports the use of sustainable packaging substrates |

| Lubrication | Automated, minimal-lubrication system | Decreases fluid use and prevents contamination |

| Lifecycle Design | Modular architecture with 10-year core chassis support | Extends machinery life, reduces e-waste |

FAQ: Intelligent Packaging Line Series

What makes an Intelligent Packaging Line Series "sustainable"?

A sustainable Intelligent Packaging Line Series goes beyond energy savings. It encompasses a holistic design philosophy that reduces material waste, supports recycled content, maximizes equipment longevity through robust construction, and employs smart software to optimize all resource inputs, thereby lowering the total environmental footprint of the packaging operation.

Does focusing on sustainability compromise the speed or reliability of the Fortran line?

Absolutely not. The Fortran Intelligent Packaging Line Series is engineered to enhance performance through sustainability. Features like energy-efficient motors reduce heat loss, improving component stability. Precision material handling decreases jams and errors, boosting overall equipment effectiveness (OEE). Sustainability and high-speed reliability are mutually reinforcing goals in our design.

How does the Fortran series help us meet our corporate sustainability targets?

Our Intelligent Packaging Line Series provides quantifiable data on key metrics. The control system tracks exact energy usage, material yield, and waste generation per production run. This transparent reporting supplies you with the accurate, auditable data needed to document carbon footprint reduction and progress towards ESG (Environmental, Social, and Governance) goals for stakeholders and regulators.

Choosing the right technology partner is crucial for a greener future. Fortran’s commitment is embedded in every machine we build. Our Intelligent Packaging Line Series is more than an investment in productivity; it's an investment in a sustainable and profitable future for your business.

Ready to see how our sustainable intelligence can transform your output? Contact us today for a detailed consultation and a tailored analysis of your production line.