The instruction of Coil Slitting Machine

2025-05-09

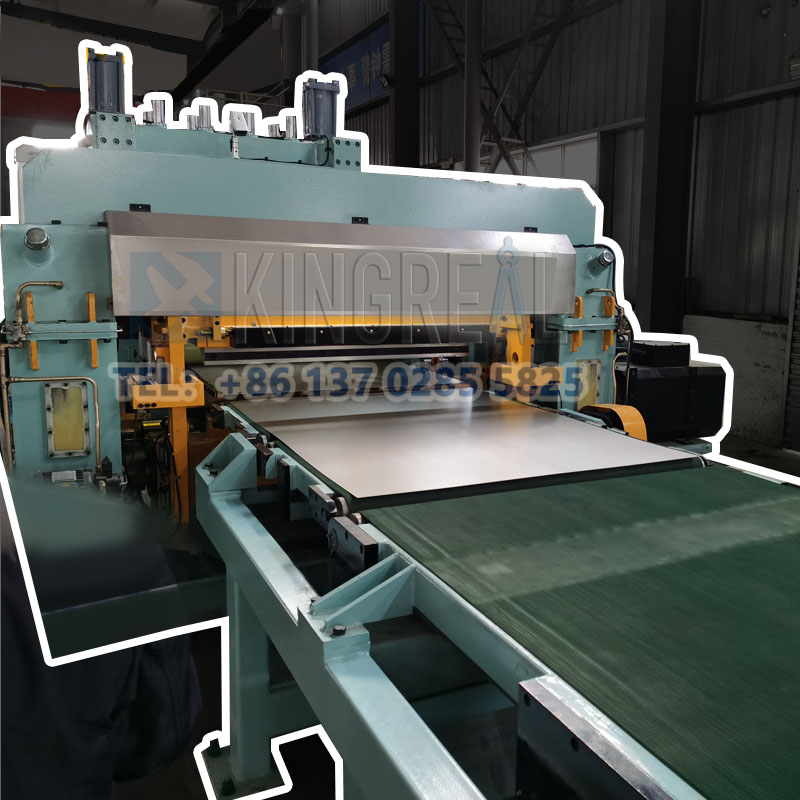

A Coil Slitting Machine is used to cut wide coils of material—typically metal—into narrower strips. Here's a basic overview of its operation and instructions:

Main Components

Uncoiler – Holds and unwinds the master coil.

Pinch Roll & Leveler – Feeds and flattens the material.

Slitter Head – Contains rotary knives that slit the coil to the desired widths.

Recoiler – Rewinds the slit strips into smaller coils.

Tension Stand/Separator – Maintains proper tension and guides strips.

Basic Operating Instructions

Setup

Load the master coil onto the uncoiler.

Thread the material through pinch rollers, leveler, slitter, and separator.

Align rotary knives according to the required strip widths.

Ensure separator discs are set to maintain strip alignment.

Operation

Start the machine and slowly feed the material through.

Monitor slitting accuracy, knife condition, and strip alignment.

Adjust speed and tension settings as needed to maintain quality.

Continuously monitor for any burrs or misalignments.

Shutdown

Stop feeding material and turn off the slitting unit.

Remove recoiled slit coils carefully.

Inspect and clean knives and rollers.

Log production data and maintenance needs.

Safety Tips

Always wear protective gear (gloves, eye protection).

Never reach into the machine while it’s running.

Regularly inspect knives and rotating parts.

Follow lockout/tagout procedures during maintenance.

If you are interested in our products or have any questions, please feel free to contact us and we will reply you within 24 hours.