what are common materials in making MLCC Machine?

2025-04-28

In short: MLCC production equipment needs to be super precise, chemically resistant, and durable because MLCCs involve very thin ceramic layers and delicate electrode materials.

Here are the common materials used in building the machines:

1. Stainless Steel (SUS304, SUS316, etc.)

Usage: Structural frames, chemical tanks, piping.

Why: Corrosion resistance (especially during slurry processing and electrode printing where chemicals are involved).

2. Aluminum (Al7075, Al6061, etc.)

Usage: Machine frames, moving parts, lightweight structural components.

Why: Lightweight but strong, easy to machine, good for high-speed moving parts.

3. Ceramics (Alumina, Zirconia)

Usage: Nozzles, guides, precision fixtures, cutting tools.

Why: Extremely hard and wear-resistant, non-reactive with powders and slurries.

4. High-Precision Alloys (Tool Steel, Tungsten Carbide)

Usage: Molds for sheet pressing, cutting tools for green sheets.

Why: Needs to withstand high pressure and repeated cycles without deformation.

5. Specialty Coatings (Teflon, Ceramic Coatings)

Usage: Surface coatings inside slurry tanks, rollers.

Why: Non-stick and chemical-resistant surfaces prevent material buildup.

6. Engineering Plastics (PEEK, PTFE, Nylon)

Usage: Bearings, bushings, some non-load critical parts.

Why: Low friction, chemical resistance, electrical insulation.

7. Precision Glass or Quartz

Usage: Inspection windows, laser processing guides.

Why: High optical clarity, chemical resistance.

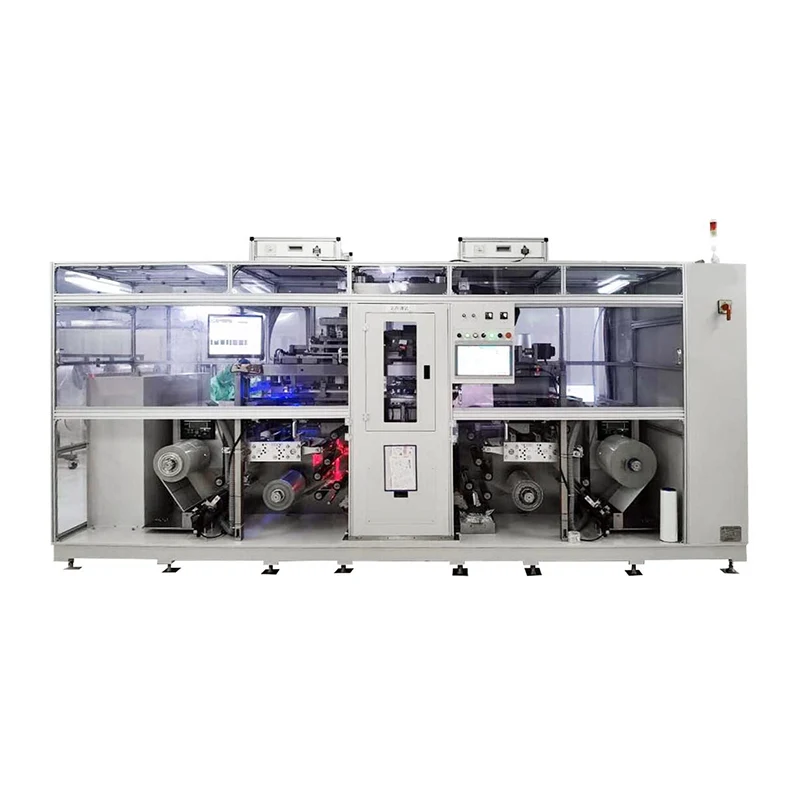

Example parts of an MLCC machine using these materials:

Tape casting machines → Stainless steel frame, ceramic blades.

Lamination press → Tool steel molds, precision load frames.

Cutting machine → Tungsten carbide or ceramic blades.

Electrode printing → Stainless steel ink system, Teflon-coated rollers.

Stacker → Aluminum arms with ceramic tips.

The company's main business includes design, research and development, intelligent equipment for chip electronic components, system integration, high-precision motion control, and manufacturing of high-precision equipment. If you are interested in our products or have any questions, please feel free to contact us.