What are the Key Features of a High-Speed Auto Roll to Roll Rewinder

2026-01-05

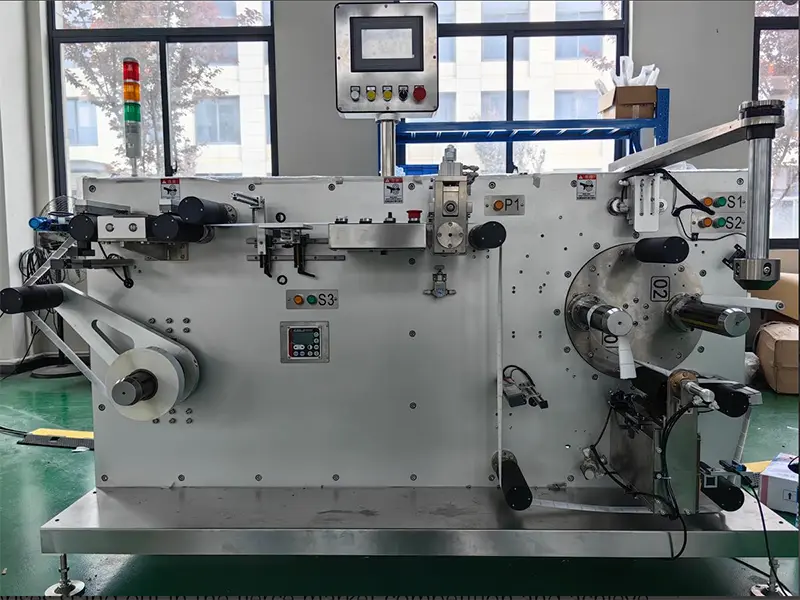

In the demanding world of roll-to-roll converting, efficiency and precision are non-negotiable. A high-speed Auto Roll To Roll Rewinder is the engine that drives productivity, transforming large master rolls into perfectly wound finished rolls. For businesses aiming to maximize output and minimize waste, understanding the core features of this equipment is critical. At WEIJU, we engineer advanced rewinding solutions that integrate these essential features to deliver unparalleled performance and reliability for our clients.

The defining features of a premium high-speed Auto Roll To Roll Rewinder can be categorized into three pillars: Precision, Automation, and Durability.

Precision Control & Tension Management:

-

Closed-Loop Tension Control: Ensures consistent material tension from start to finish, preventing issues like wrinkles, stretching, or telescoping.

-

Web Guiding Systems: Automatically corrects lateral web movement, guaranteeing edge-to-edge alignment for a perfectly straight roll.

-

Programmable Slitting Modes: Offers razor, shear, or crush slitting options controlled via a user-friendly HMI for clean, burr-free edges.

Automation & Intelligence:

-

Automatic Core Loading & Ejection: Reduces manual handling, increases safety, and significantly boosts machine cycle times.

-

Touchscreen HMI with Recipe Storage: Allows operators to save and recall settings for different jobs instantly, reducing setup time and human error.

-

Integrated Length/Speed Counters: Provides precise control over roll length and diameter, ensuring consistency across every batch.

Durability & Operational Safety:

-

Robust Frame Construction: Built with heavy-duty materials to withstand high-speed operation and ensure long-term stability.

-

Safety Guards & Emergency Stops: Complies with international safety standards to protect operators.

-

Easy-Access Maintenance Points: Designed for simplified servicing to minimize downtime.

The following table summarizes how these features translate into tangible benefits for your operation:

| Feature Category | WEIJU Implementation | Direct Benefit |

|---|---|---|

| Precision | Servo-driven tension & guiding | Reduces material waste, improves product quality |

| Automation | PLC with recipe management | Increases throughput, enables quick changeovers |

| Durability | Reinforced steel construction | Lowers total cost of ownership, ensures uptime |

Auto Roll To Roll Rewinder FAQ

Q: How does an Auto Roll To Roll Rewinder handle different material thicknesses?

A: A high-quality rewinder like those from WEIJU uses adaptive tension control systems. The PLC automatically adjusts tension parameters based on the material's yield strength and thickness, which is pre-set in the job recipe. This ensures delicate films and heavier substrates are wound with optimal pressure to prevent damage or loosening.

Q: What is the importance of a turret design in a high-speed rewinder?

A: A turret or dual-position design is crucial for non-stop production. While one set of shafts is winding the finished roll, the other position can be prepared with new cores. This allows for continuous operation without stopping the machine to unload and reload, maximizing productivity especially in high-volume settings.

Q: Can these rewinders integrate with existing printing or coating lines?

A: Absolutely. Modern Auto Roll To Roll Rewinders are designed for seamless integration. WEIJU equipment features standardized communication protocols (like Ethernet/IP) and can be synchronized with upstream processes such as printers, coaters, or laminators. This creates a continuous, streamlined production line from start to finish.

Investing in a high-speed Auto Roll To Roll Rewinder is an investment in the future efficiency and quality of your converting operation. The key features outlined above form the foundation of a machine that not only meets today's demands but also adapts to tomorrow's challenges. WEIJU is committed to providing robust, intelligent, and precise rewinding solutions that empower your business to achieve more.

Ready to enhance your production line with a precision-engineered rewinding solution? Contact us today to discuss your specific requirements and discover how WEIJU can optimize your roll-to-roll process.