What is a Cap Threader?

2025-08-04

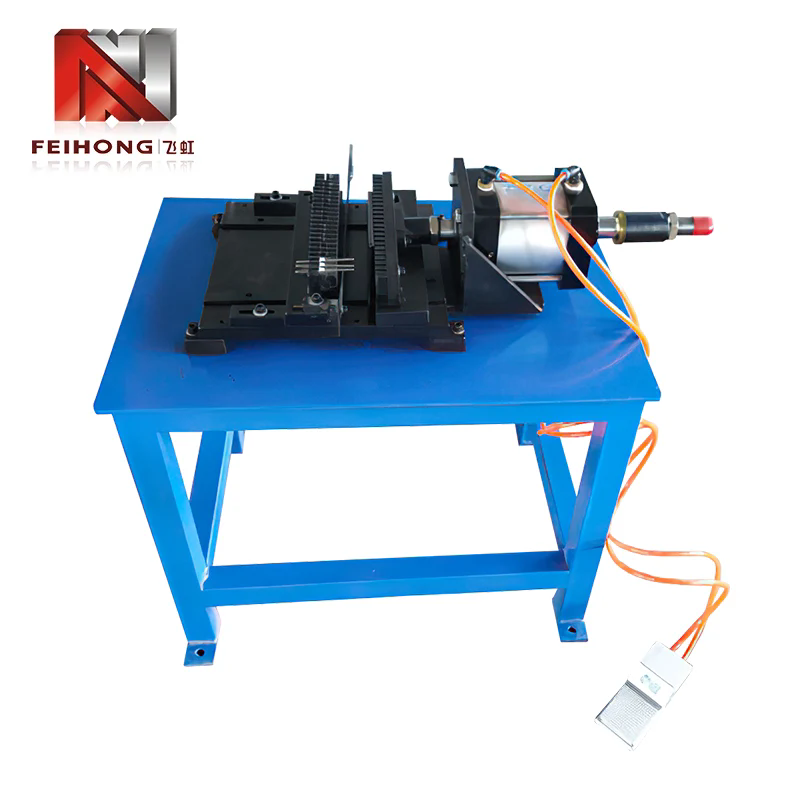

In the world of manufacturing, packaging, and various industrial applications, a cap threader is an essential piece of equipment. Whether you are involved in the production of bottles, jars, or other containers that require threaded caps, understanding the ins and outs of cap threaders can significantly impact your operations. In this comprehensive guide, we will explore what a cap threader is, its key product parameters, and answer some of the most frequently asked questions about these important machines.

The Significance of a Cap Threader

Key Product Parameters of Our Cap Threaders

1. Manual Cap Threaders

|

Parameter

|

Details

|

|

Threading Range

|

Can handle container neck diameters from 15mm to 80mm. This wide range makes it suitable for a variety of container sizes, from small vials to larger jars.

|

|

Thread Type

|

Capable of creating both standard metric and imperial threads. Whether you need M10x1.5 threads for a European - style container or 3/8 - 16 UNF threads for an American - style one, our manual cap threader can meet your needs.

|

|

Operation Mechanism

|

Features a simple and ergonomic hand - crank operation. This allows for precise control over the threading process, making it ideal for small - scale production runs or for those who require a high level of customization.

|

|

Material Compatibility

|

Can work with various materials, including plastic (such as HDPE, LDPE, and PET), glass, and metal (aluminum and some types of steel). This versatility ensures that you can use it for different product packaging requirements.

|

2. Automatic Cap Threaders

|

Parameter

|

Details

|

|

Production Capacity

|

Our automatic cap threaders can process up to 1000 containers per hour, depending on the model. This high - speed production makes it suitable for large - scale manufacturing facilities.

|

|

Threading Precision

|

Achieves a threading accuracy of ±0.05mm. This high level of precision ensures that the caps fit perfectly on the containers, reducing the risk of leaks and improving product quality.

|

|

Control System

|

Equipped with a user - friendly PLC (Programmable Logic Controller) control system. This allows for easy programming of different threading parameters, such as thread pitch, depth, and speed. You can also set up different production batches with specific threading requirements.

|

|

Safety Features

|

Comes with multiple safety features, including emergency stop buttons, safety guards to prevent accidental contact with moving parts, and sensors to detect any abnormal operations. These safety features ensure the well - being of your operators and the smooth running of the machine.

|

Cap Threader FAQ

Q: How do I choose between a manual and an automatic cap threader?

Q: Can a cap threader be adjusted to create different thread sizes?

A: Yes, most of our cap threaders, both manual and automatic, are adjustable to create different thread sizes. For manual cap threaders, the adjustment is usually done by changing the threading dies. We provide a set of interchangeable dies with different thread specifications, allowing you to switch between different thread sizes as needed. For automatic cap threaders, the adjustment is more sophisticated. The PLC control system enables you to input the desired thread parameters, such as thread pitch and diameter. The machine then automatically adjusts the threading mechanism to create the specified thread size. This flexibility makes our cap threaders suitable for a wide range of container and cap types, accommodating various industry standards and customer requirements.