What Makes Precision Foam Engraving Equipment Essential for Modern Manufacturing

2025-10-21

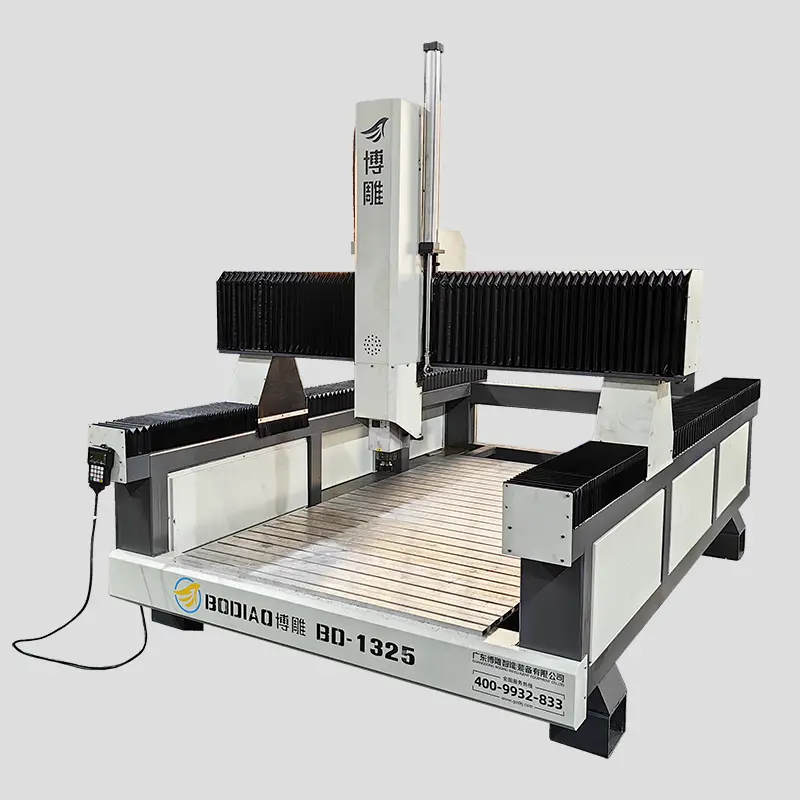

Working at BoDiao, I’ve spent years helping clients find smarter ways to improve their production lines. One of the most common questions we receive is how to achieve high-accuracy engraving on foam materials without wasting time or effort. The answer always comes down to one machine — the CNC Foam Engraving Machine. This piece of equipment has transformed how industries like packaging, sculpture design, and automotive prototyping work with foam.

Why Is Precision So Important in Foam Engraving

Foam is lightweight and versatile, but it’s also delicate. Traditional cutting or manual engraving can easily damage the surface, leading to uneven results and material waste. A Precision Foam Engraving Equipment allows for exact control of every motion path, ensuring clean edges and smooth surfaces. In my experience, precision determines not only product quality but also overall production efficiency.

How Does a CNC Foam Engraving Machine Work

The machine operates through a computer-controlled system that translates 3D designs into precise cutting paths. It uses high-speed spindles and durable engraving tools to carve intricate patterns, shapes, and textures directly onto foam blocks. Our BoDiao engineers continuously refine motion control and spindle stability, resulting in smooth, vibration-free engraving even at high feed speeds.

What Are the Key Features and Technical Specifications

To give you a clear idea of what sets our machine apart, here’s a detailed overview of the BoDiao Precision Foam Engraving Equipment:

| Parameter | Specification |

|---|---|

| Working Area | 2000mm × 3000mm × 800mm (customizable) |

| Spindle Power | 9.0 kW High-Speed Air-Cooling Spindle |

| Engraving Accuracy | ±0.02 mm |

| Maximum Feed Rate | 25,000 mm/min |

| Control System | Advanced DSP / SYNTEC Controller |

| Compatible Materials | Foam, EPS, EPE, PU, PVC Board |

| Tool Change | Automatic Tool Changer (6–8 tools) |

| Transmission | Taiwan HIWIN Linear Guide + Helical Rack |

| Power Supply | AC 380V / 50Hz |

| Software Compatibility | ArtCAM, Type3, UG, Powermill, JD Paint |

Each component is designed to maintain long-term reliability under industrial workloads. Clients often tell us that after switching to BoDiao equipment, their waste rate dropped by over 30% and engraving speed increased dramatically.

What Problems Does It Solve for Businesses

From what I’ve seen in real production environments, companies struggle with:

-

Inconsistent engraving quality caused by manual operation

-

High material waste due to inaccurate depth control

-

Limited design flexibility when using older or generic CNC systems

-

Downtime and maintenance costs from unstable machines

Our BoDiao solution addresses these issues directly. The machine’s integrated control system ensures consistent depth across every pass, while its high-speed spindle shortens project turnaround time. Whether you’re cutting foam molds or creating display models, precision translates to profit.

How Easy Is It to Operate and Maintain

Another question we often get is whether the system requires a highly skilled operator. The answer is no — the BoDiao CNC Foam Engraving Machine is designed for simplicity. With an intuitive interface, pre-set toolpaths, and automatic calibration, even first-time users can start engraving within hours. Regular maintenance is minimal — just keep the spindle clean, check the lubrication system, and the equipment runs smoothly for years.

Why Choose BoDiao as Your CNC Foam Engraving Machine Supplier

Over the years, BoDiao has built its reputation as a trusted manufacturer and supplier in CNC solutions. Our factory uses international-grade components, strict quality inspection, and continuous R&D to meet clients’ exact needs. We don’t just sell machines — we deliver full technical support, training, and custom design options.

Ready to Upgrade Your Foam Engraving Process

If you’re looking to improve precision, efficiency, and reliability in foam processing, our BoDiao CNC Foam Engraving Machine is the right choice. We’re here to help you optimize your production workflow and reach new levels of accuracy.

👉 Contact us today to request a free quotation, schedule a live demo, or get expert advice tailored to your project needs. Let’s create something precise — together.