What Makes the Powered Belt Conveyor Series Ideal for Furniture Manufacturing

2025-11-10

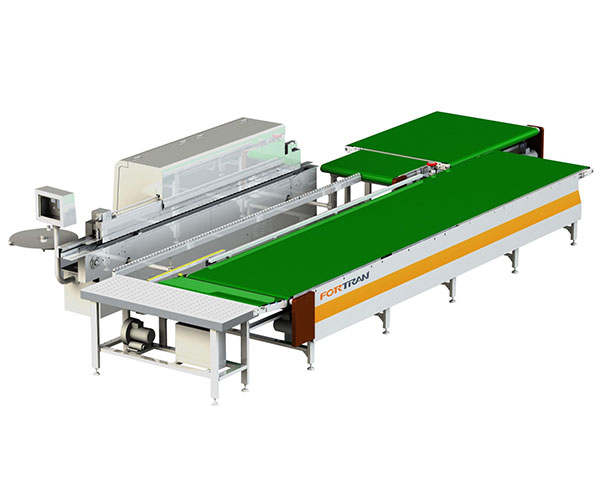

At Fortran, we often get asked why our Powered Belt Conveyor Series is such a perfect fit for furniture plants. The answer lies in its unique ability to handle the delicate, bulky, and irregular shapes common in this industry. Unlike generic systems, our series is engineered specifically for the challenges of moving sofas, tables, and cabinets efficiently and without damage.

What Key Features Protect Furniture from Damage During Transport

Surface protection is paramount. Our Powered Belt Conveyor Series incorporates several critical features to prevent scratches and dents.

-

Soft-Top Belting: A pliable belt surface that cushions furniture items.

-

Consistent Speed Control: Eliminates jerky movements that cause items to shift or collide.

-

Low-Friction Rollers: Ensure smooth transition points, preventing impact marks.

| Specification | Benefit for Furniture Manufacturing |

|---|---|

| Wide Belt Options (e.g., 24-inch) | Provides stable support for wide items like tabletops and mattresses, preventing tipping. |

| Adjustable Speed Control | Allows the line pace to be perfectly synced with assembly, upholstery, or packaging stations. |

| High Weight Capacity | Capably handles the significant weight of dense wooden furniture or large sectionals without strain. |

FAQ

What is the maximum weight capacity for your Powered Belt Conveyor Series

Our standard Fortran models are robust enough to handle up to 1,500 pounds, making them ideal for moving heavy wooden armoires, office desks, and fully assembled sofas without any risk of system strain or failure.

Can the system be customized for different factory layouts

Absolutely A key advantage of the Fortran Powered Belt Conveyor Series is its modular design It can be configured with curves, inclines, and multiple zones to fit any factory floor plan, ensuring a seamless flow from production to shipping.

How does the conveyor protect delicate finished surfaces

We use specialized low-tension, non-marking belts that provide a gentle grip Furthermore, our precision engineering ensures the belt tracks perfectly straight, eliminating the lateral rubbing that can scuff and damage high-gloss finishes and delicate woods.

Choosing the right conveyor system is an investment in the quality and efficiency of your production line. If you are looking to eliminate damage and boost throughput, our experts are ready to assist. Contact us today to get a customized solution for your furniture manufacturing needs.