What Raw Materials Are Used in a WPC Decking Profile Machine

2025-12-19

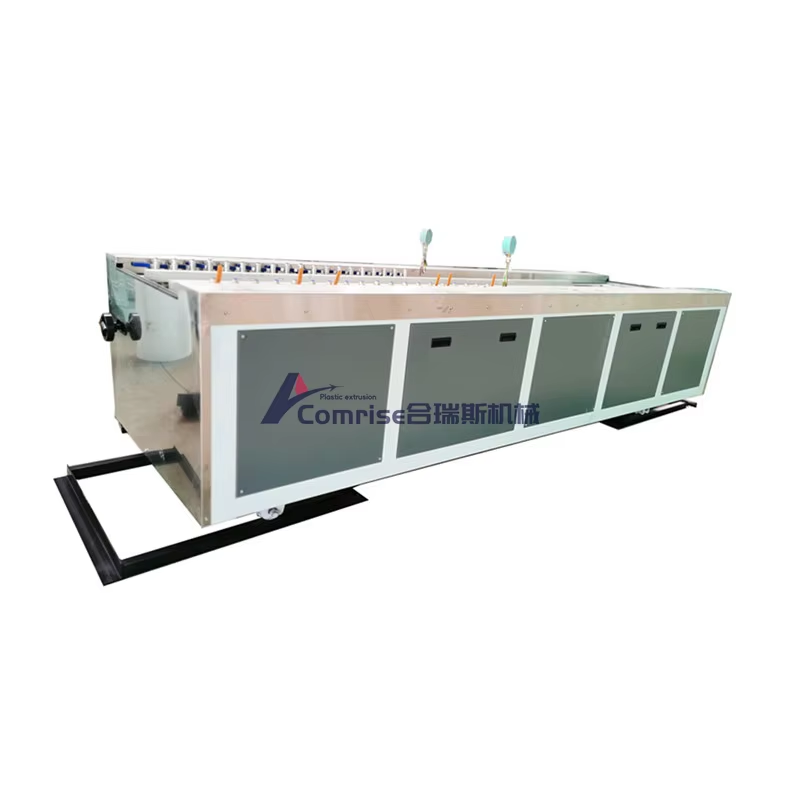

When investing in a WPC Decking Profile Machine, understanding the raw materials it processes is crucial for product quality and business success. At Comrise, we believe that a superior machine must be engineered to handle a precise blend of ingredients, transforming them into durable, beautiful composite decking. The core materials are a mixture of wood fibers, polymers, and specialized additives, each playing a vital role.

Primary Raw Materials & Their Functions:

-

Wood Fiber/Flour: Typically 50-60% of the mix. It provides the natural wood-like texture and rigidity. Common sources include hardwood and softwood flour from pine, bamboo, or recycled wood waste.

-

Polymer Matrix (Plastic): Making up 30-40%, this acts as the binder. We engineer our Comrise machines to process both Virgin PVC/PP for superior color consistency and Recycled Plastics (like HDPE from bottles) for eco-friendly profiles.

-

Coupling Agents: Chemical additives (1-3%) that create a strong bond between the hydrophobic plastic and hydrophilic wood fiber, dramatically enhancing strength and water resistance.

-

Lubricants: Reduce friction during extrusion in the WPC Decking Profile Machine, ensuring a smooth surface finish and protecting the machine's screws and barrels.

-

Pigments & UV Stabilizers: UV inhibitors prevent fading, while high-quality pigments ensure long-lasting, uniform color throughout the decking profile.

-

Foaming Agents: For producing lightweight, low-density WPC boards with excellent thermal insulation properties.

To achieve optimal results, the formula must be perfectly balanced. Our Comrise machines are calibrated for high precision. Key technical parameters include:

| Parameter | Comrise Machine Specification | Impact on Final Product |

|---|---|---|

| Wood Plastic Ratio | Adjustable from 40:60 to 70:30 | Controls strength, density, and wood-like feel. |

| Moisture Content | <1.5% requirement | Prevents bubbling and ensures profile surface quality. |

| Extrusion Temperature | 150-190°C Precise Control | Ensures complete plastic melting and material fusion. |

| Output Capacity | 200-800 kg/h Models Available | Determines production efficiency and business scale. |

WPC Decking Profile Machine FAQ

Q: Can I use 100% recycled plastic in a WPC Decking Profile Machine?

A: While Comrise machines are designed to handle high percentages of recycled content, using 100% recycled plastic is not recommended. Recycled plastic can have inconsistent melt flow and degradation. A blend with virgin polymer is typically required to maintain structural integrity, impact strength, and a consistent extrusion process for your decking profiles.

Q: How fine does the wood flour need to be for optimal production?

A: For smooth extrusion and a high-quality surface finish, the wood particle size should be between 80 to 120 mesh. Finer flour allows for better encapsulation by the plastic polymer, resulting in a more waterproof product and reducing wear on the machine's extrusion screw and barrel, a key design focus for Comrise equipment.

Q: Why are additives like coupling agents so important in the WPC mix?

A: Wood and plastic are naturally incompatible materials. Coupling agents act as a chemical bridge, creating a strong bond between them. This significantly reduces water absorption, increases the mechanical strength (like flexural modulus), and improves the long-term durability of the decking produced by your WPC Decking Profile Machine, preventing cracking and warping.

Ready to transform these raw materials into profitable, high-quality decking? The right WPC Decking Profile Machine is the engine of your success. Contact us at Comrise today to discuss your production goals. Our experts will provide a detailed analysis and recommend the perfect machine configuration for your specific raw material formula and output targets. Let's build the future of decking together.