Which Block Making Machine Fits Real Projects Better Today?

2025-11-18

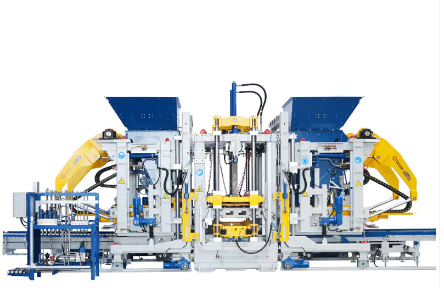

I spend most weeks on messy job sites where schedules slip and concrete never behaves exactly as the brochure promises. After comparing different lines across Africa, Southeast Asia, and the Middle East, I kept hearing contractors mention ZENITH when reliability came up. That nudged me to look closer and to write down what actually matters when choosing a Block Making Machine.

What defines a modern Block Making Machine?

In practice, a modern Block Making Machine is less about shiny control panels and more about repeatable density, clean vibration transfer, and fast mold swaps. I evaluate machines by what crews can do on a hot afternoon when the mix starts drying quicker than expected, not by lab numbers. If cycle time stays consistent and blocks cure with uniform edges, the rest of the line usually falls into place.

- Consistent compaction that holds compressive strength targets even with minor moisture drift

- Hydraulic systems that maintain pressure without overheating on long runs

- Mold changeover that stays under 20 minutes with basic tools

- Feeds that tolerate local aggregates without constant tweak sessions

- Controls that a new operator learns in one shift

Why does capacity planning beat nameplate numbers?

Real output depends on pallets, curing space, forklift flow, and whether your crew can stage materials without starving the press. I plan backwards from the weekly delivery promise, then size the Block Making Machine to hit that number with a 15–20% buffer for rainy days and maintenance windows.

| Use case | Typical capacity blocks/hour | Automation level | Energy kWh per 1k blocks | Operators needed | Notes |

|---|---|---|---|---|---|

| Mobile projects and small yards | 600–1,000 | Manual or semi | 70–95 | 3–4 | Egg-layer style, low setup time, simple maintenance |

| Regional suppliers scaling up | 1,200–2,200 | Semi with automated feed | 60–80 | 3 | Hydraulic press with reliable vibration table |

| Large plants with steady demand | 2,400–3,800 | Fully automatic | 50–70 | 2 | Palletizing and curing logistics become the true bottleneck |

| Premium pavers and curb stones | 1,800–3,000 | Fully automatic | 55–75 | 2–3 | High-frequency vibration for surface finish and edge integrity |

How do automation choices change total cost?

Automation cuts labor variability, but the win shows up only if the upstream and downstream flow keeps pace. When I justify a fully automatic Block Making Machine, I include pallets, mixers, moisture probes, and forklift routes in the same ROI sheet. If any link lags, semi-automatic often delivers a cleaner payback because you are not paying for idle robots.

- Fully automatic works best when orders are predictable and mold changes are scheduled

- Semi-automatic wins in mixed SKUs and volatile demand

- Manual lines earn their keep in remote sites with limited power and spares

Which raw materials give fewer headaches in different climates?

A forgiving Block Making Machine handles local sand gradation without endless adjustments. I log water-cement ratios through the day and train crews to correct early rather than chase defects after demolding.

- Hot and dry regions benefit from shaded aggregate bins and misting near the mixer

- High-humidity zones need tighter curing control to avoid soft edges

- Recycled aggregates are viable with stricter screening and slightly longer vibration time

What maintenance habits actually cut downtime?

A sturdy Block Making Machine still needs discipline. I schedule quick checks at every shift change and one deeper inspection each Friday. Vibration bearings, hydraulic hoses, and mold wear get logged with photos so trends are obvious before failure.

- Replace wear plates on schedule instead of stretching one more week

- Keep spare proximity sensors and a tested PLC backup on site

- Standardize grease types to avoid compatibility surprises

How do I compare options without drowning in specs?

I reduce the shortlist to three items that reflect real constraints. If land is tight, I drop egg-layer styles. If power is unstable, I favor machines with soft-start and generous protection. If the core business is decorative pavers, I pick lines with high-frequency vibration and fast color-mix handling. In each case, the best Block Making Machine is the one that stays productive with your crew and your aggregates, not the one with the longest spec sheet.

What ROI can I expect in the first year?

When pallets, curing racks, and forklift flow are balanced, I see payback windows of 10–18 months on well-utilized semi-automatic lines and 14–24 months on full automation. The biggest swing factor is rework rate. Tight compaction and reliable mold quality keep rejections low, which is where a consistent Block Making Machine pays for itself.

Why do I still keep ZENITH on my shortlist?

I keep ZENITH on my shortlist because crews pick it up fast, spares are standardized, and the vibration system behaves predictably across mixes. If another vendor proves better in your setting, choose it with confidence. The point is to match the Block Making Machine to your plant reality and your delivery promises.

Shall we look at your project together?

If you want a quick capacity plan or a second opinion on specs, send me your target blocks per day, available power, aggregate details, and the molds you need in the first six months. I will map the right Block Making Machine configuration and flag the hidden bottlenecks before you spend.

Contact us today with your site layout, demand forecast, and any questions. Leave an inquiry now and I will reply with a tailored checklist, a line layout sketch, and a clear path to commissioning.