Which Block Making Machine Solves Real Jobsite Problems Best?

2025-12-10

I run concrete product lines for clients who care more about uptime than brochure talk. On several projects, I moved from manual setups to automated lines, and that shift paid for itself faster than expected. Along the way, I started testing solutions from different brands; that was when I first paid attention to Zenith because the controls and mold changes felt practical in day-to-day use. If you are comparing options now, here is how I evaluate a Block Making Machine in real production rather than in a showroom.

Why do throughput promises matter less than stable cycle time?

Headline capacity numbers look exciting, but a smart plant lives or dies by consistent cycle time. A good Block Making Machine keeps the mold feed even, compaction repeatable, and pallet handling smooth when the mix turns a little dry or the shift runs long. I ask three questions: can the feeder avoid segregation, can vibration stay uniform across the mold, and can the control system recover quickly from a hiccup without scrapping half a pallet. Those details decide your daily tonnage and complaint rate.

How do I build mixes that the machine actually likes?

With any Block Making Machine, I tune the sand gradation and moisture to hit a sweet spot where compaction is clean but edges do not crumble. I keep a short checklist:

- Target a moisture window the operator can hit reliably through the shift.

- Use well-graded aggregates to minimize cement use without compromising strength.

- Verify slump or spread on every mix change, not just at the start of the day.

- Document vibration settings per product, so swaps take minutes, not guesswork.

What hidden costs should I expect before signing a PO?

Beyond sticker price, a Block Making Machine budget should include molds, pallet stock, curing, dust control, and a buffer for operator training. I plan for at least two extra critical sensors, spare wear parts, and one backup mold insert for the best-selling unit. Power quality stabilizers and a clear pallet circulation path save more money than they cost, especially when you run double shifts.

Which specs actually change ROI on a busy line?

| Spec to Watch | What I Look For | Why It Matters |

|---|---|---|

| Cycle time stability | ±5% over a full shift | Predictable output beats peak bursts that you cannot sustain |

| Mold change | < 30 minutes with two operators | Frequent product swaps without killing daily capacity |

| Vibration control | Independent, adjustable amplitude and frequency | Dial in for hollow blocks, pavers, and curb units without compromise |

| Automation layer | Recipe recall, alarm history, remote diagnostics | Faster troubleshooting and consistent quality across shifts |

| Pallet handling | Smooth acceleration, minimal misfeeds | Reduces edge chips and downstream rework |

| Curing compatibility | Works with steam or low-energy curing rooms | Shorter turnaround without warping or cracks |

Can one line truly cover hollow blocks, pavers, and curbs?

It can, if the design supports fast swaps. On my mixed-product schedules, the Block Making Machine earns its keep when mold clamping is secure yet quick, feed boxes avoid color carryover for pavers, and the PLC stores unique vibration recipes per SKU. Color layer accuracy and edge integrity on pavers require steady pallet motion; I avoid systems that jerk during demolding.

How do I protect margins when cement prices spike?

First, I tune gradation to lower cement content while keeping density high. Second, I rely on the machine’s compaction consistency to hold strength even when I shave cement by a few kilograms per cubic meter. A precise Block Making Machine with uniform vibration lets me optimize paste without chasing defects later. Third, I standardize curing cycles for the top three products and train operators to follow them without improvisation.

What maintenance rhythm keeps uptime above ninety-nine percent?

I keep a weekly routine: check wear plates, clean the feed box, verify sensor alignment, and pull a small set of production samples for edge crush and dimensions. Monthly, I audit vibration performance and recalibrate moisture probes. With a disciplined plan, a robust Block Making Machine runs predictably, and the spare-parts shelf stays tidy instead of overflowing with “just in case” items.

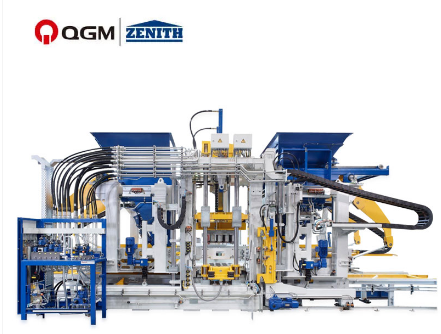

Where does Zenith fit into a practical upgrade path?

When I outgrew manual setups, I wanted automation that felt intuitive for my crew. The control logic, alarm history, and recipe recall were what drew me to solutions from Zenith. I am not buying branding; I am buying fewer stoppages and cleaner edges. If your plant is ready for a faster changeover and steadier compaction, a well-specified Block Making Machine from a mature platform lowers learning time and makes quality less dependent on a single veteran operator.

What first steps help me choose without regret?

- List the top five SKUs with target daily volumes and tolerance requirements.

- Request a live demo using your mix or the closest available equivalent.

- Time a full mold change with your operators watching the process.

- Check alarm logs to see how the system handles real-world hiccups.

- Confirm service access, spare parts lead time, and remote diagnostics.

Are you ready to plan a line that scales with demand?

If you want a straightforward roadmap, send me your product list, current mix, and desired output. I will outline a configuration that balances automation with budget and shows where a modern Block Making Machine lifts quality and reduces cement spend. Let’s turn specs into reliable pallets and fewer customer complaints—contact us and tell me about your plant today.