Why Does a Cement Block Molding Machine Decide My Profit Curve?

2025-12-10

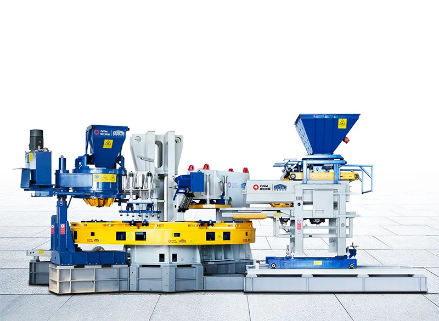

When I set out to upgrade my block plant, I realized the machine at the center is not just steel and hydraulics—it is the rhythm section of the whole business. As I evaluated options, I kept returning to what QGM does differently and how a modern Cement Block Molding Machine turns unpredictable workshop days into repeatable output. In this guide, I’ll share the questions I asked, the checks I ran on-site, and the simple math that showed me why a robust Cement Block Molding Machine drives quality, cost, and growth. If you are debating models, automation levels, or ROI timelines, my path will help you avoid guesswork—and choose a Cement Block Molding Machine that scales without drama.

What problems does a Cement Block Molding Machine quietly solve for me?

- Dimensional drift — The right vibration and pressure profile keeps block height consistent, reducing on-site complaints and rework.

- Wasted cement — Stable compaction means less over-cementing to hit strength targets, trimming mix costs without risking breaks.

- Bottlenecks between stations — Synchronized feeding, molding, and palletizing keeps flow continuous instead of stop-start chaos.

- Operator dependency — Parameter libraries and guided recipes cut the learning curve and preserve quality through shift changes.

- Unplanned downtime — Sensor feedback and intuitive HMIs surface issues before they turn into production halts.

How do I judge molding quality without a lab on site?

I rely on simple field checks before I even pour test cubes. During trials, I inspect edges and faces for chips, measure block height at all corners, and watch how quickly fresh blocks release from the mold. A precise Cement Block Molding Machine gives me sharp arrises, uniform height within ±1–2 mm (product-dependent), and smooth demolding without hairline tears. Then I compare early-age handling strength after a short set; if stacks don’t deform under their own weight, the pressure–vibration profile is doing its job.

Which specs actually matter when brochures all look the same?

- Vibration energy delivered to the mix — Not just kW on paper; I need stable amplitude under load for dense, even compaction.

- Hydraulic responsiveness — Valving and loop design control how quickly the press hits and holds target pressure without shock.

- Frame stiffness — A rigid frame prevents energy loss and keeps mold alignment true over long runs.

- Cycle time integrity — Fast is useless if it’s fast-and-inconsistent; I look for short cycles that repeat within tight tolerances.

- Recipe management — I want saved profiles for pavers, hollow blocks, and solids so the line changes over in minutes, not hours.

Where does my cost per block really come from?

I break it into mix cost, energy, labor, and scrap. A capable Cement Block Molding Machine helps on all four: lower cement ratios for the same strength, tuned motors and hydraulics for power efficiency, fewer operators thanks to automation, and less scrap due to dimensional stability. The big surprise for me was how much scrap quietly ate margins; shaving even 1–2% rejection with better compaction paid for upgrades faster than I expected.

How do automation choices change my daily reality?

- Semi-automatic — Good for starting up; lower capex but more operator touch points and variability.

- Fully automatic — Consistency jumps. Pallet handling, curing queueing, and stacking become predictable, and shift output becomes a reliable number on my planner.

- Data visibility — Alarms, counters, and trend charts let me adjust mix moisture or dwell time before problems cascade.

What should my site checklist look like before I sign anything?

- Watch a live cycle from feed to ejection; time and repeat it at least ten times.

- Check block dimensions across different cavities of the mold—uniformity is non-negotiable.

- Listen for vibration harmonics; a clean tone under load often signals efficient energy transfer.

- Open the HMI recipe page; confirm I can store, copy, and lock parameters.

- Review wear parts access; I want minutes, not hours, to service plates, bushings, and seals.

Why do material and mix control decide whether specs become reality?

Even the best Cement Block Molding Machine cannot save a poor mix. I standardize aggregate grading, monitor moisture with quick tests, and train operators to adjust water on the fly within a narrow band. When the mix is right, the machine’s vibration profile translates directly into density and face quality. When the mix is wrong, the line chases symptoms all day.

What differences should I expect between entry and premium tiers?

| Factor | Entry Tier | Premium Tier | Impact on My Plant |

|---|---|---|---|

| Frame and Guides | Basic stiffness, more periodic realignment | High-rigidity frames, precision guides | Premium keeps tolerances stable over long runs |

| Vibration System | Fixed settings, limited amplitude control | Adjustable, load-stable vibration | Consistent density and clean edges across products |

| Hydraulics | Slower response, pressure overshoot | Fast, repeatable pressure curves | Smoother compaction and faster cycles |

| Automation | Semi-automatic, operator-dependent | Fully automatic with recipe control | Higher throughput and less variability |

| Maintenance Access | Longer service windows | Tool-friendly layouts and diagnostics | Less downtime and clearer fault tracing |

How do I protect my molds and keep output crisp over time?

- Rotate molds by SKU to spread wear and preserve cavity geometry.

- Keep feed uniform so fine and coarse fractions don’t segregate at the mouth of the mold box.

- Use scheduled torque checks for tie rods and critical fasteners; vibration loosens what time forgets.

- Log cavity measurements every set number of cycles; small drifts alert me before quality slips.

What KPIs tell me the machine is making money instead of noise?

- First-pass yield — Percentage of blocks that pass without rework.

- Cycles per hour — Measured and stable across shifts, not just peak bursts.

- kWh per pallet — Drops as vibration and hydraulics are tuned.

- Mix cost per block — Falls when density is achieved without over-cementing.

- Labor per 1,000 blocks — Decreases with automation and layout optimization.

Why did I settle on a high-consistency platform instead of chasing the lowest price?

Because my customers buy deadlines and uniformity as much as they buy blocks. A reliable Cement Block Molding Machine let me quote tighter schedules, accept larger orders, and sleep on pouring nights. When service and parts are predictable, my plant runs like a calendar instead of a coin toss.

How does QGM fit into my selection logic without buzzwords?

What won me over were grounded details: steady vibration under load, clean parameter control, straightforward maintenance, and a support team that understands the whole line from raw material feed to curing logistics. In real terms, that meant fewer adjustments mid-shift and fewer calls to the yard to hold a truck. The result was simple—more sellable blocks per pallet, with fewer stories attached.

What action plan should I follow this week if I want results fast?

- Audit my current rejects and measure true cost per block including scrap and delays.

- Run a comparative trial on a candidate Cement Block Molding Machine using my own mix and molds.

- Capture vibration, cycle time, and height dispersion data over at least ten cycles per SKU.

- Map the operator path and remove unnecessary touch points with simple fixtures or automation.

- Lock proven recipes and train the team on changeover discipline.

Will this investment still make sense if demand spikes next season?

That’s where scalability matters. A well-specified Cement Block Molding Machine has headroom in vibration energy, hydraulic flow, and control logic to handle extra SKUs and higher throughput without tearing up molds or burning operators out. When orders jumped for me, I increased shift length and added pallets rather than rewriting the whole plant.

Ready to turn consistency into margin?

If you want a practical walkthrough tailored to your mix design, site layout, and product list, tell me what you’re building and what’s holding you back. I’ll share a checkpoint sheet you can use during a live demo and help you compare options for a machine that fits your targets. When you’re ready, contact us to discuss a line built around a proven Cement Block Molding Machine and turn stable quality into stable profit—use the form on this page to contact us and start your evaluation today.