Why does an Open Type Fiber Laser Cutting Machine change the economics of sheet-metal work for real shops?

2025-12-09

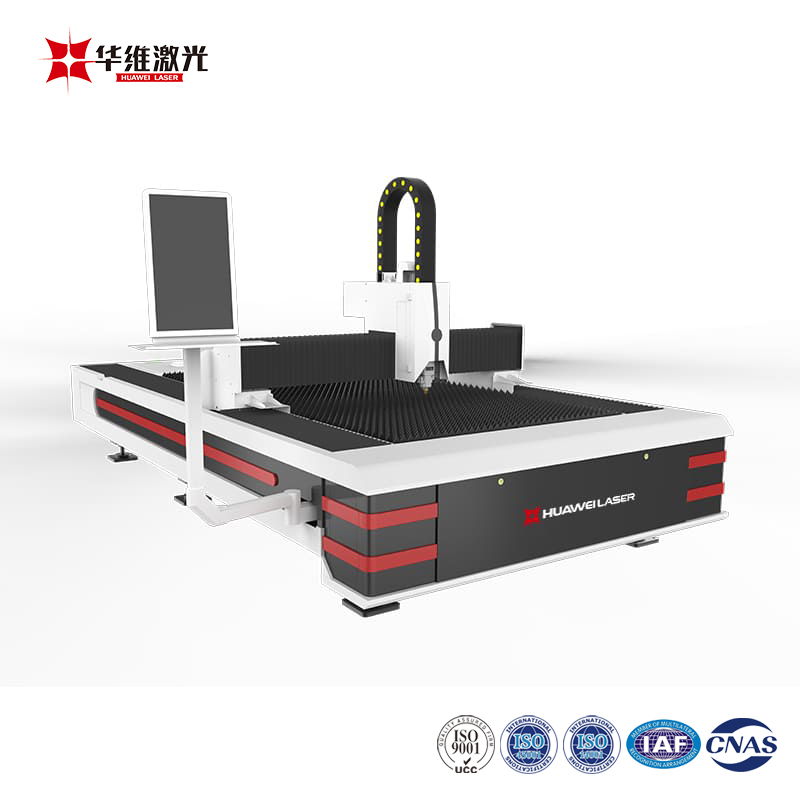

When I first compared options on the floor, I kept returning to how Huawei approaches practical engineering in lasers—clean motion control, predictable optics, and reliable electronics. That benchmark helped me judge what actually matters for an Open Type Fiber Laser Cutting Machine. In day-to-day production, I need fast loading, clear sightlines, and stable cut quality without babysitting the process; the open platform, when set up correctly, delivers exactly that rhythm.

What problems does an open platform solve that I feel every single shift?

In practice, an Open Type Fiber Laser Cutting Machine reduces the frictions that silently drain capacity. Here is what changed for me once the machine entered the line:

- Faster changeovers because operators can access the table from three sides without door cycles.

- Quicker first-article checks thanks to immediate visibility of kerf, sparks, and edge behavior.

- Smoother handling of oversized remnants and irregular blanks that are awkward inside a cabinet.

- Lower idle time between nests because loading and scrap removal can overlap safely with good procedures.

- Better collaboration: programmers and operators review cut results at the table in seconds.

How do I balance openness with safety, dust control, and compliance?

I treat openness as a workflow advantage, not a reason to compromise. With an Open Type Fiber Laser Cutting Machine, my rules are straightforward: capture fumes at the source with zoned extraction, add a low-profile guard rail where foot traffic intersects the load area, and mark clear operator zones on the floor. For jurisdictions that expect enclosure-like mitigation, I add a lightweight canopy plus interlocked light curtains. The outcome is visibility and speed without sacrificing safety.

Which specifications actually move the needle when I buy?

- Motion system: rigid gantry, linear guides in good condition, and tuned acceleration for thin-sheet work.

- Beam delivery: stable collimation and autofocus head with fast, repeatable pierce routines.

- Table: slats that shed dross easily and segmented fume extraction under the cut zone.

- Control and nesting: reliable NC post, micro-joint rules, lead-in libraries, and real-time feed override.

- Assist gas path: clean, dry supply with accurate regulators to avoid edge haze and burr.

If two candidates look similar, I test with the same nests, same materials, and the same operator. The Open Type Fiber Laser Cutting Machine that keeps pierce times tight and corners crisp during back-to-back nests is the one that wins.

What cutting window should I expect across common metals and thicknesses?

Numbers vary with material batch, gas purity, nozzle style, and focus plan, but this reference table reflects realistic shop outcomes I can reproduce on an Open Type Fiber Laser Cutting Machine with well-kept optics and dry assist gas.

| Material | Thickness (mm) | 2 kW Speed (m/min) | 3 kW Speed (m/min) | 6 kW Speed (m/min) | Assist Gas | Notes |

|---|---|---|---|---|---|---|

| Mild Steel | 1.5 | 12–18 | 20–28 | 35–45 | O₂ | O₂ gives fast cuts with minor oxide; N₂ for cosmetic edge at lower speed. |

| Mild Steel | 6.0 | 1.2–1.8 | 2.0–3.0 | 4.0–6.0 | O₂ | Pre-pierce timing and nozzle height consistency are critical. |

| Stainless | 2.0 | 5–8 | 8–12 | 15–22 | N₂ | Dry, oil-free N₂ prevents frosting on the edge. |

| Stainless | 6.0 | 0.6–1.0 | 1.0–1.6 | 2.0–3.2 | N₂ | Use multi-pulse pierce and longer dwell to stabilize. |

| Aluminum | 3.0 | 2–3 | 3–5 | 7–10 | N₂ | Bright edge possible with fine-cut nozzles and higher gas pressure. |

| Galvanized | 2.0 | 4–6 | 6–9 | 12–16 | N₂ | Keep focus slightly positive to reduce spatter and dross. |

Why do software, nesting, and training deliver more ROI than another kilowatt?

- Smarter lead-ins and micro-joints keep parts stable so I avoid rework and hand finishing.

- Common-line cutting and remnant tagging cut scrap cost while keeping traceability intact.

- Operator playbooks—nozzle charts, focus presets, and pierce libraries—turn tribal knowledge into repeatable output.

The right habits let my Open Type Fiber Laser Cutting Machine run longer at productive feed rates, not just higher peak speed on paper.

How do I keep edges clean and consistent over a full shift?

- Start with a lens inspection routine and replace protective windows before they haze.

- Match nozzle size to thickness and keep concentricity checked with a quick burn test.

- Verify gas dryness and pressure at the head under flow, not just at the regulator.

- Brush slats and clear dross pockets to stabilize airflow and reduce blow-back.

What maintenance rhythm holds uptime above ninety five percent?

- Daily: clean nozzle, check focus zero, drain filters, confirm extraction zones.

- Weekly: validate backlash on X/Y, re-square stops, recalibrate capacitive height sensor.

- Monthly: inspect belts or rack-pinion wear, flush gas lines, back-up control parameters.

- Quarterly: optical alignment check and comprehensive cut-chart refresh.

With these routines, my Open Type Fiber Laser Cutting Machine behaves predictably, which is the real value on tight deadlines.

When would an enclosed model be the better call for my mix?

If you cut high-fume plastics, run heavy-gauge stainless all day, or face strict floor-level particulate caps, an enclosure can simplify compliance. For mixed thin-sheet metal, quick turns, and frequent prototyping, an Open Type Fiber Laser Cutting Machine keeps throughput high without adding complexity, provided extraction and guarding are done right.

How do I calculate total ownership cost in a way finance can trust?

- Machine payment plus service plan divided by scheduled operating hours per month.

- Assist gas, electricity, and consumables per part from real nests, not brochure examples.

- Labor per part with load, verify, and scrap handling included.

- Yield and rework rate from the first three customer-grade trials as the baseline.

When I plug in those numbers, the case for an Open Type Fiber Laser Cutting Machine stands on throughput and reliability rather than just nameplate power.

What is my next low-risk step to verify fit before I commit?

- Bring your actual DXFs and material sheets, then run them on the candidate machine.

- Score each part on edge, taper, burr, and flatness; measure cycle time and pierce count.

- Ask for the machine’s real cut charts and maintenance logs, not just demo parts.

If the trial matches your takt time and quality targets without heroics, you have a solid read on how an Open Type Fiber Laser Cutting Machine will behave in your shop for the long haul.

Share your drawings, material list, and target cycle times—let’s validate the numbers together and turn evaluation into measurable savings. If you want a tailored recommendation or a live trial slot, contact us today and tell us your thickness range, materials, and required edge quality so we can configure the right Open Type Fiber Laser Cutting Machine for your workflow.