Why Should I Choose a Brick Machinery Pallet for My Production Line?

2025-08-18

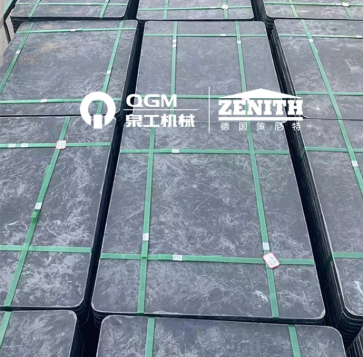

As someone deeply involved in the construction machinery industry, I often ask myself how to improve efficiency while maintaining product quality. One solution that I have found extremely effective is using a Brick Machinery Pallet. From my experience, this component is not just a simple support structure; it plays a crucial role in the brick manufacturing process.

What Is the Primary Function of a Brick Machinery Pallet?

A Brick Machinery Pallet serves as a durable platform that holds bricks during the molding, pressing, and curing stages. It ensures that bricks maintain their shape and size consistency, which is critical for high-quality production. At Quangong Block Machinery Co., Ltd, our pallets are designed to withstand heavy loads, resist wear and tear, and reduce maintenance frequency.

Here is a simple overview of the pallet features:

| Feature | Description | Benefit |

|---|---|---|

| Material | High-strength steel or alloy | Long-lasting, resists deformation |

| Size | Standard and customized options | Fits different machines |

| Weight Capacity | Up to 500 kg per pallet | Supports heavy brick loads without breaking |

| Surface Treatment | Anti-rust coating | Prolongs service life |

| Compatibility | Suitable for automatic brick machines | Easy integration into production line |

These features make my operations smoother and help avoid downtime caused by pallet failure.

How Does Using a Brick Machinery Pallet Improve Production?

In my experience, integrating Brick Machinery Pallet into the production line greatly enhances efficiency. By providing a stable and uniform platform for bricks, the pallets reduce material loss and minimize manual handling. Workers can focus more on quality control rather than adjusting misaligned bricks.

Key benefits include:

-

Faster production cycles due to stable brick stacking

-

Consistent brick size and shape for higher-quality output

-

Reduced labor costs as fewer adjustments are needed

-

Enhanced safety in the production area

These advantages demonstrate why I never underestimate the importance of high-quality pallets in brick manufacturing.

Why Is Choosing the Right Brick Machinery Pallet Important?

Selecting the right pallet is a decision that directly affects productivity and machine longevity. At Quangong Block Machinery Co., Ltd, our pallets are engineered to match specific brick machine models, ensuring perfect alignment and minimal wear on machinery. Poor-quality pallets can lead to frequent breakdowns, increased maintenance costs, and inconsistent brick quality.

Summary of Importance:

-

Maintains brick consistency and quality

-

Reduces maintenance and operational costs

-

Supports higher production efficiency

-

Increases worker safety

Investing in a reliable Brick Machinery Pallet is not just a choice; it is a necessity for anyone serious about professional brick production. My team and I have experienced firsthand how these pallets transform the workflow and maximize output.

For anyone looking to optimize their brick manufacturing line, our pallets at Quangong Block Machinery Co., Ltd are the ideal solution. Upgrade your production today and experience unmatched stability, efficiency, and durability! Contact us!