Why Should You Choose a Concrete Brick Making Machine for Your Business?

2025-08-21

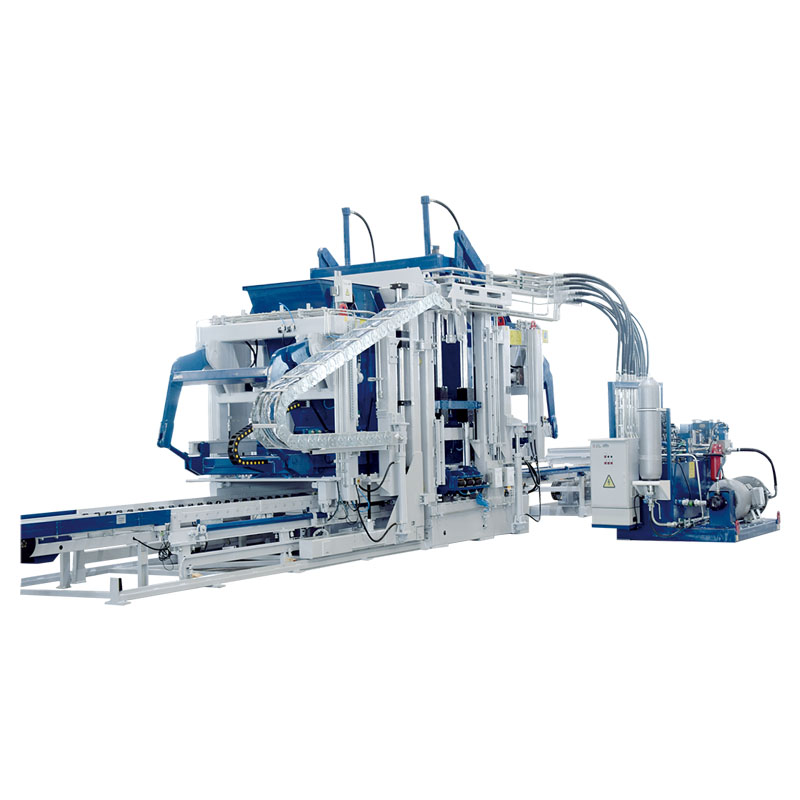

In today's fast-developing construction industry, the demand for durable, cost-effective, and eco-friendly building materials is higher than ever. One of the most innovative solutions to meet this demand is the concrete brick making machine. For decades, brick manufacturing has relied on labor-intensive processes or outdated equipment that limits efficiency and scalability. However, with the introduction of advanced automated systems, companies like Quangong Machinery Co., Ltd provide solutions that combine precision engineering, high output, and long-lasting performance.

When I first encountered a modern concrete brick making machine, I wondered: Can this equipment really transform the way we build? The answer is a definite yes. Let's explore the specifications, advantages, and industry impact of these machines in detail.

What Is the Role of a Concrete Brick Making Machine?

A concrete brick making machine is specialized equipment designed to manufacture bricks, blocks, and pavers using cement, sand, stone, and other raw materials. Unlike traditional manual methods, these machines compress and mold materials under high pressure, ensuring uniform density and strength in each unit produced.

The role of this machine is not limited to simple brick production.

Key Features and Parameters of Our Concrete Brick Making Machine

At Quangong Machinery Co., Ltd, we design and manufacture concrete brick making machines that meet international standards. Our machines are engineered for both large-scale factories and medium-sized enterprises. Below is a breakdown of the technical specifications and features:

Technical Parameters

| Parameter | Specification |

|---|---|

| Machine Model | QGM QT Series (various models available) |

| Production Capacity | 4,000 – 12,000 pcs/day (depending on model) |

| Brick Size Options | Standard, hollow, solid, interlocking, pavers |

| Power Requirement | 22 – 75 kW |

| Cycle Time | 15 – 25 seconds per cycle |

| Operating Mode | Fully automatic with PLC control system |

| Raw Materials Supported | Cement, sand, gravel, fly ash, construction waste |

| Pallet Size | 850×680mm to 1400×900mm |

Why Should Businesses Invest in a Concrete Brick Making Machine?

I once asked myself: Is investing in such heavy equipment worth it for my company? After analyzing the benefits, I realized the answer was absolutely yes. Here's why:

-

High Return on Investment

With large production capacity and low operating costs, companies quickly recover their investment. -

Consistent Quality

Automated molding guarantees bricks with uniform dimensions and compressive strength. -

Flexibility

The ability to produce multiple shapes and sizes meets diverse project requirements. -

Environmental Responsibility

Many models allow the use of industrial waste, reducing environmental impact. -

Competitive Edge

Delivering projects faster and with better materials gives your business a significant advantage.

Frequently Asked Questions (FAQ)

Q1: What raw materials are required for a concrete brick making machine?

A1: Typically, the machine uses a mixture of cement, sand, gravel, water, and sometimes fly ash or construction waste. The exact proportions depend on the type of brick being produced, but the machine ensures the mix is compacted and molded into high-quality bricks.

Q2: How many bricks can a concrete brick making machine produce in one day?

A2: Depending on the model, production capacity ranges between 4,000 and 12,000 bricks per day. For example, a medium-sized machine might deliver around 8,000 standard blocks daily, ensuring consistent supply for large construction projects.

Q3: What is the lifespan of a concrete brick making machine?

A3: With proper maintenance, the lifespan can exceed 15 years. The machine's robust steel frame, high-quality hydraulic system, and modular design ensure durability. Regular cleaning, lubrication, and replacement of wear parts will extend its performance and reliability.

Why Partner with Quangong Machinery Co., Ltd?

Over the past decades, Quangong Machinery Co., Ltd has established itself as a trusted manufacturer of high-end construction machinery. We don't just sell machines; we provide comprehensive solutions that include:

-

Customizable models to suit specific production requirements.

-

Global installation and training services to ensure smooth operations.

-

After-sales support with spare parts and technical assistance.

-

Sustainable production methods to align with global environmental goals.

When I needed reliable equipment for a large-scale project, Quangong Machinery delivered not just a machine but also peace of mind. Their technical team supported my staff, and the machine ran flawlessly even under continuous production.

Conclusion

The concrete brick making machine is more than just equipment—it is a smart investment for the future of construction. Whether you are a contractor, a developer, or an entrepreneur in the building materials industry, this machine ensures high productivity, consistent quality, and long-term profitability.

If you are ready to scale your business with reliable, high-performance machinery, get in touch with Quangong Machinery Co., Ltd today. Our team of experts is here to provide professional consultation, tailored solutions, and world-class support.

Contact Quangong Machinery Co., Ltd now and take the first step toward smarter, faster, and greener construction.