Why Should You Choose the High Speed 15L Single Station Blow Molding Machine?

2025-09-08

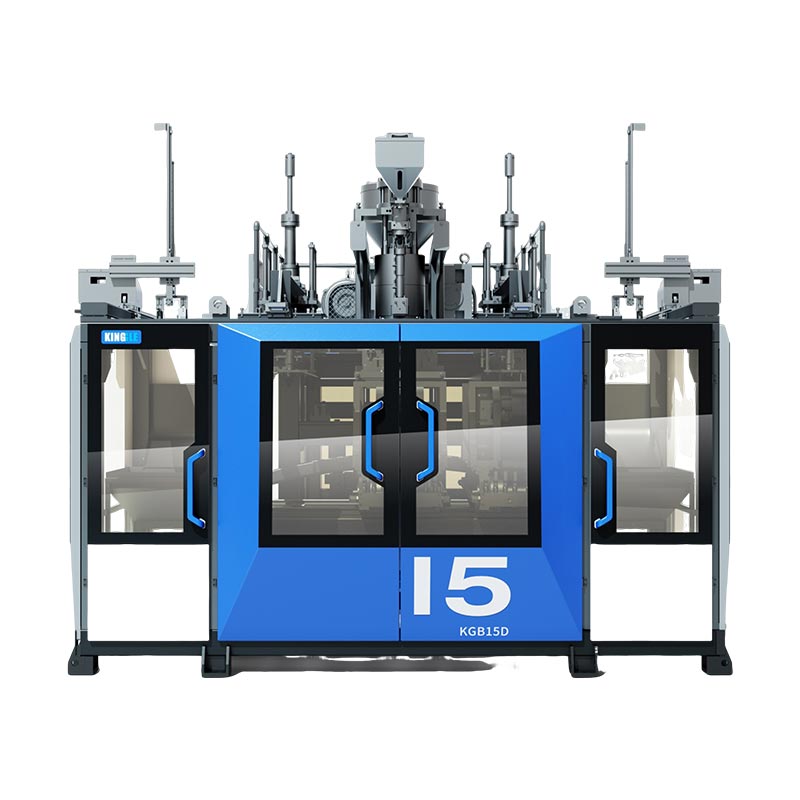

In today's competitive plastic manufacturing industry, efficiency, durability, and precision are essential. The High Speed 15L Single Station Blow Molding Machine is designed to meet the rising demand for high-volume production without compromising quality. Many companies seek machinery that not only improves productivity but also lowers operational costs. That's exactly where this advanced blow molding machine demonstrates its value.

Manufactured with strict adherence to international standards, this machine provides an exceptional balance between performance and cost-effectiveness. With its user-friendly design, advanced automation, and outstanding production stability, it is an ideal solution for manufacturers producing medium-sized containers, drums, or other plastic products.

Key Features of the High Speed 15L Single Station Blow Molding Machine

-

High-speed production for improved efficiency and consistent output.

-

Single station design offering precise molding control with simplified operation.

-

Energy-saving technology that minimizes power consumption.

-

Durable components ensuring longer equipment lifespan.

-

Advanced automation system with easy-to-use controls.

-

Wide application range for 15L containers such as chemical bottles, lubricant packaging, household products, and more.

-

Compact structure that saves space and reduces maintenance requirements.

Technical Parameters

The following table provides a clear overview of the core specifications of the High Speed 15L Single Station Blow Molding Machine. These parameters highlight the machine's professional design and its suitability for various industries:

| Parameter | Specification |

|---|---|

| Machine Type | High Speed 15L Single Station Blow Molding Machine |

| Max Container Volume | 15 Liters |

| Production Capacity | 120 – 180 pcs/hr (depending on product) |

| Screw Diameter | 80 mm |

| Screw L/D Ratio | 25:1 |

| Plasticizing Capacity | 95 kg/hr |

| Clamping Force | 120 kN |

| Die Head Type | Single Head (Optional Multi-Layer) |

| Heating Zones | 4 Zones |

| Total Power | 60 kW |

| Average Energy Consumption | 35 – 40 kW/hr |

| Air Consumption | 1.0 m³/min at 0.8 MPa |

| Cooling Water Consumption | 70 L/min at 12–15°C |

| Machine Dimension (L×W×H) | 4.5m × 2.5m × 3.0m |

| Net Weight | 7,500 kg |

These parameters make it clear that this blow molding machine is built to ensure strong output capacity, stability, and reliability in continuous industrial production.

Applications and Benefits

The High Speed 15L Single Station Blow Molding Machine is widely used in multiple industries. Its flexibility and robust structure make it ideal for manufacturers who require consistent production of mid-sized containers.

-

Chemical Industry: Perfect for producing high-strength chemical containers resistant to corrosion.

-

Lubricant Packaging: Ensures consistent thickness and durability for oil and lubricant bottles.

-

Household Industry: Used for large detergent bottles, cleaning product packaging, and more.

-

Food & Beverage: Capable of producing safe, hygienic plastic containers.

Major Benefits:

-

High Productivity: Reduces cycle times while maintaining precision.

-

Cost Efficiency: Energy-saving system reduces electricity bills.

-

Stable Operation: Designed for continuous 24/7 operation with minimal downtime.

-

User-Friendly: Easy control system reduces operator training costs.

-

Durability: Strong clamping system ensures long-term consistent molding.

FAQ: High Speed 15L Single Station Blow Molding Machine

Q1: What materials can the High Speed 15L Single Station Blow Molding Machine process?

A1: It can process a wide range of thermoplastic materials such as HDPE, LDPE, PP, and other commonly used polymers. This versatility makes it suitable for manufacturing containers used in multiple industries.

Q2: How energy-efficient is the machine compared to traditional models?

A2: Thanks to its upgraded heating system and optimized extruder design, the High Speed 15L Single Station Blow Molding Machine consumes approximately 20% less energy than conventional models while maintaining higher output.

Q3: What is the typical lifespan of this blow molding machine?

A3: With regular maintenance, the machine can last over 10–12 years. Critical parts such as the screw, barrel, and clamping unit are made of wear-resistant materials to ensure longevity.

Q4: How difficult is it to maintain and operate this machine?

A4: The design emphasizes ease of operation. Operators can quickly learn the control system, and maintenance is straightforward with accessible components. Ningbo Kinggle Machinery Co., Ltd. also provides professional technical support and after-sales service to minimize downtime.

Why Work with Ningbo Kinggle Machinery Co., Ltd.?

When selecting advanced blow molding machinery, the manufacturer's reliability is as important as the machine's performance. Ningbo Kinggle Machinery Co., Ltd. has been delivering high-quality plastic machinery for years, known for combining innovation with strong technical expertise. By choosing this machine, customers gain not only efficient equipment but also comprehensive service and support.

From installation to training and ongoing technical consultation, the company ensures smooth operations for clients across different industries. With a proven track record in global markets, Ningbo Kinggle Machinery Co., Ltd. continues to be a trusted partner for manufacturers who demand excellence in plastic production.

Conclusion

The High Speed 15L Single Station Blow Molding Machine is more than just a piece of equipment—it is a long-term investment in efficiency, cost savings, and consistent product quality. With advanced features, durable construction, and the backing of Ningbo Kinggle Machinery Co., Ltd., it stands out as the smart choice for manufacturers seeking reliable blow molding solutions.

For more details or inquiries about the High Speed 15L Single Station Blow Molding Machine, please contact Ningbo Kinggle Machinery Co., Ltd. today and discover how we can support your business growth.