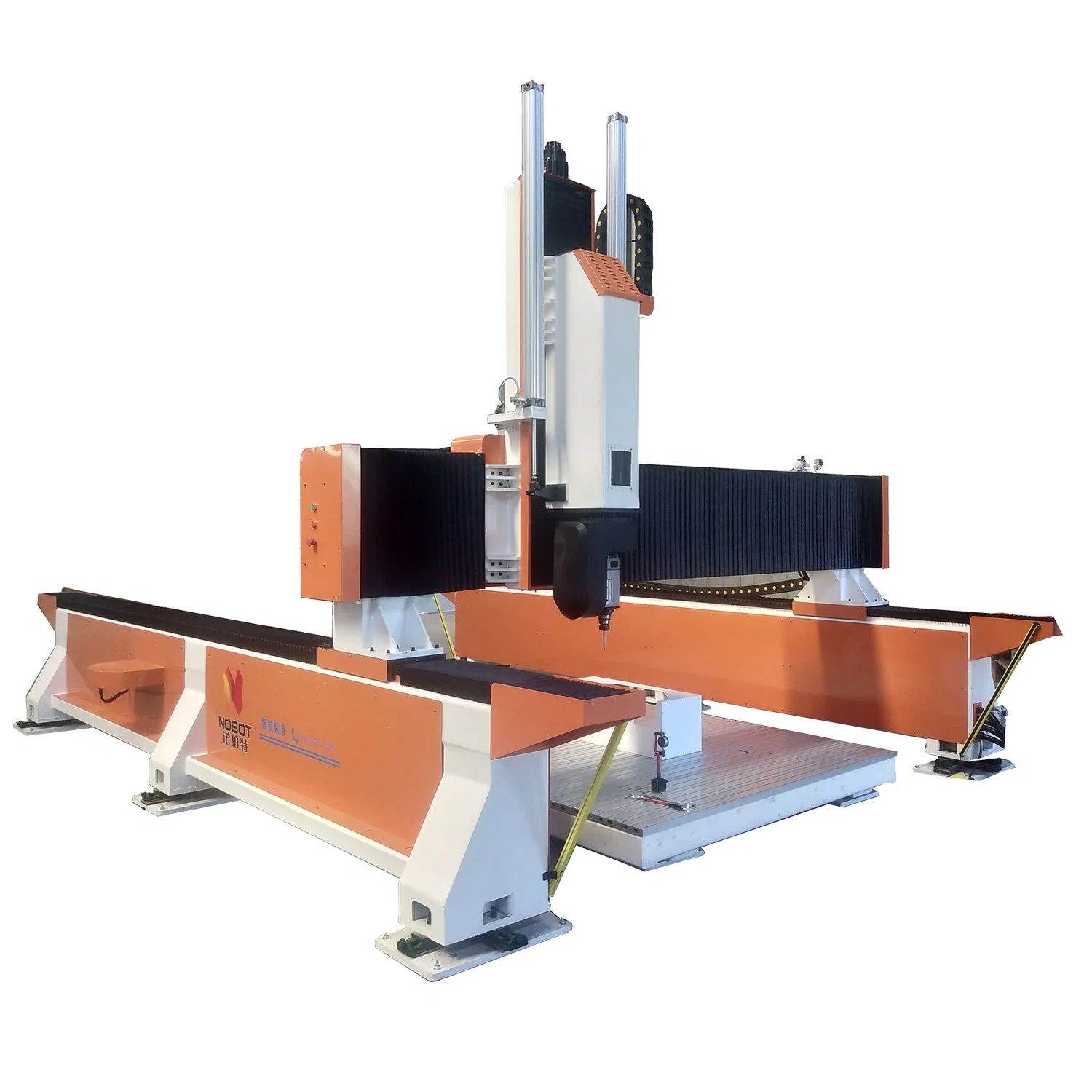

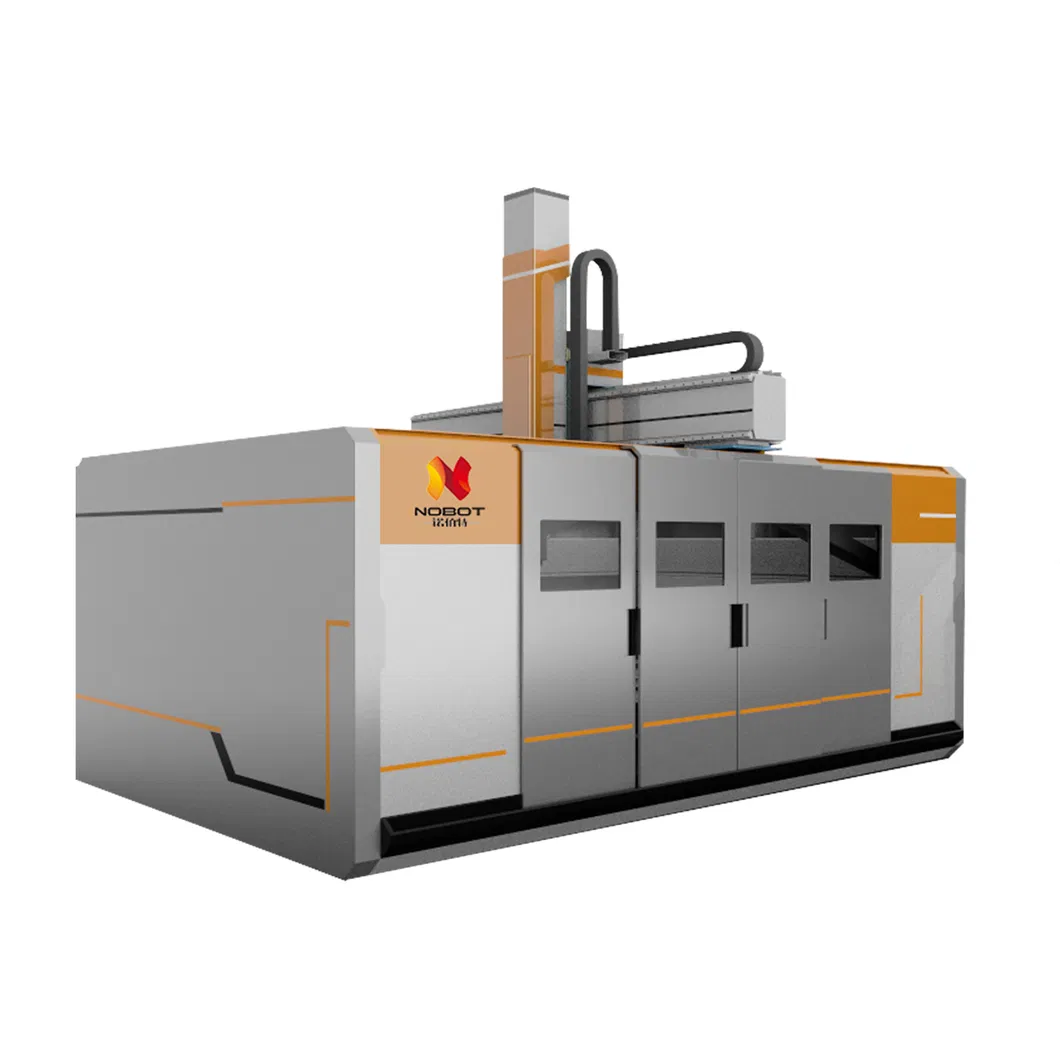

Five Axis CNC Machine Tool

Application Industries:Composite material industry: Vacuum formed plastic parts trimming, fiber glass parts trimming, rubber and plastic parts trimming and other composite material parts trimming; Automotive, Sanitary ware industry, art and craft industry, white household appliances industryApplicat......

Send Inquiry

Product Description

Application Industries:

Composite material industry: Vacuum formed plastic parts trimming, fiber glass parts trimming, rubber and plastic parts trimming and other composite material parts trimming;

Automotive, Sanitary ware industry, art and craft industry, white household appliances industry

Application materials:

Processing material: vacuum forming parts, wood, composite material, perspex, EPC, resin, plaster and GFRP etc..

Base features:

Non-metallic 5 axis moving table, fixed bridge CNC machining center

Integrated high rigidity steel frame

Working table: T-slot aluminium/ vacuum

Nobot controller

Ethernet TCP/IP, USB & Serial Port Connections

Hiteco electrospindle: 10KW

380V/50Hz power

Drive system: Yaskawa servo motor

Liner motion: Taiwan Hiwin ballscrew

Liner guide: Taiwan Hiwin rail

Laser calibrate for X & Y axes

Other Features:

Nobot numerical control system for ease of use, features high accuracy, high speed;

Diversification control for running speed, processing speed and tool dropping speed;

Hand wheel make the operation remotely;

Recirculating ball screw assembly on Z axes, and is optional to X and Y axes;

Optimized structure and configuration, increase the cost performance and reduce the running and maintenance expense;

Tailor made design enrich wide range power, dimension options.

Specification:

Working area: 2200mm for X axes, 3000mm for Y axes, 1100mm for Y axes

±540° for C axes and ±110° for A axes

Max. Spindle rpm: 20000rpm

Tool holder: HSK-F63

Max. Running speed: 25000mm/min

Max. Processing speed: 18000mm/min

Positioning accuracy: ±0.10mm/1000mm

Re-positioning accuracy: ±0.05mm/1000mm

Maximum feeding height: 1000mm

Lubrication: manual or automatic

Coolant: liquid cooling/ air cooling

RTCP(Rotating Tool Center Point) available

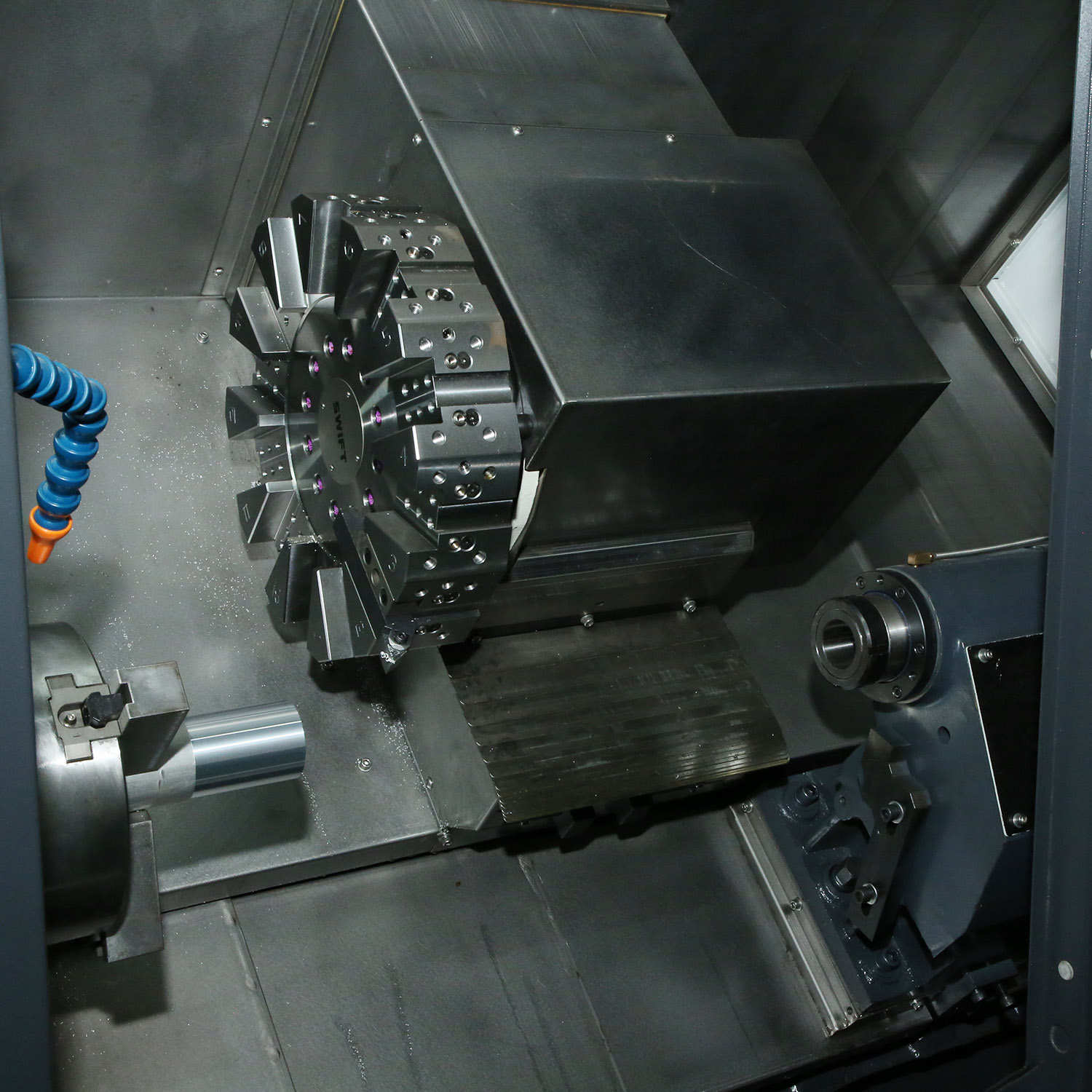

ATC (Automatic tool changer) available