Home > Products > Drilling Machine > Mt52D- 21t Advanced Siemens-System High-Precision Drilling and Milling CNC Center

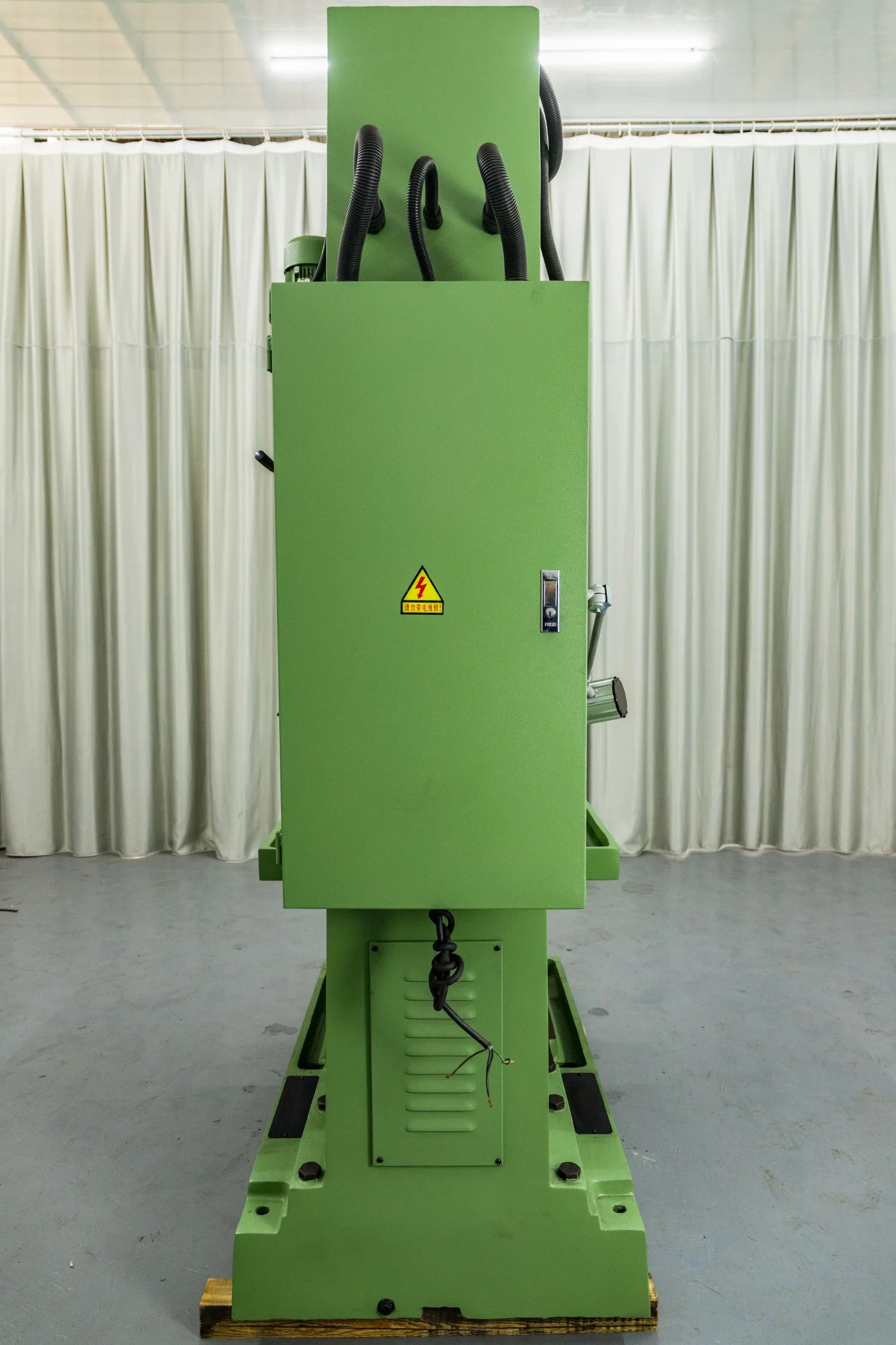

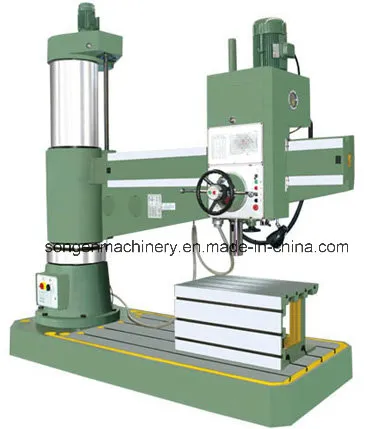

Mt52D- 21t Advanced Siemens-System High-Precision Drilling and Milling CNC Center

1.SpecificationModelMT52DItem SIEMENSTableSize 600(23.57)*380(14.93) mm(inch)Max. bearing weight 300(11.79) kg(lbs)TravelX-axis 520(20.43) mm(inch)Y-axis 400(15.71) mm(inch)Z-axis ......

Send Inquiry

Product Description

1.Specification

2. Features

Larger work table improve machining ability.

Greatly reduced tool change time to achieve high productivity (Cut to Cut 1.3s)

Optimized the shape of the structure and arrangement of ribs to enhance machine rigidity, leading to improved cutting performance.

3. Standard accessories

(1) Work Light

(2) Signal Light

(3) Foundation Plates and Bolts

(4) 14-Tool Changer

(5) Cooling System

(6) Automatic Lubricating Device

(7) Splash-proof Metal Sheet

(8) Toolkit

(9) Bed Shower

(10) Safety Door Lock

(11) Hand-operated MPG

(12) Special Technical Documents

4. Optional Accessories

(1) Hydraulic Unit

(2) NC rotary table

(3) NC Slant Rotary Worktable

(4) Hand-operated MPG

(5) Transformer (Unnecessary for SIEMENS System)

(6) Air-conditioner for Electrical Cabinet

(7) Higher Column

(8) Spraying Water from Spindle Center

(9) Spindle Cooling System

5. Part of applications

(1) auto industry

(2) medical industry

(3) military industry

(4) IT industry

(5) others

6. Factory Advantages

(1) Annual production: 2000sets.

(2) Spindle and tool changer are produced independently, based on German technology.

(3) R&D center: founded in 2006.

(4) Patents and honors: more than 60 certificates.

(5) Sales network: 9 regions, 23 offices in China; 5 branches around the world.

(6) 3 part warehouse: 1 in Shanghai, 1 in Changzhou and 1 at oveseas.

| Model | MT52D | |

| Item | SIEMENS | |

| Table | Size | 600(23.57)*380(14.93) mm(inch) |

| Max. bearing weight | 300(11.79) kg(lbs) | |

| Travel | X-axis | 520(20.43) mm(inch) |

| Y-axis | 400(15.71) mm(inch) | |

| Z-axis | 300(11.78) mm(inch) | |

| Distance from spindle to table surface | 180(7.09)-480(18.90) mm(inch) | |

| Spindle | Spindle speed | 12000(15000/20000/24000rpm) |

| Tapping speed | 6000 rpm | |

| Taper | 7/24 | |

| Feeding rate | Rapid rate X/Y/Z axes | 56(2.2)/56(2.2)/56(2.2) m/min(inch/min) |

| Cutting feeding rate | 1-22,000(866.14) mM/min(inch/min) | |

| ATC unit | Toolholder specification | BT30 |

| Pull stud type | P30T-1 | |

| Tool storage capacity | 21 pcs | |

| Max. tool length | 200(7.86) mm(inch) | |

| Max. tool diameter | 80(3.14) mm(inch) | |

| Max. tool weight | 3(6.61) kg(lbs) | |

| Tool change time | Tool to Tool | 0.8 Sec. |

| Chip to Chip | 1.3Sec. | |

| Electric motors | Spindle motor | 4.8/ 19 kw |

| Power source | Power | AC220+/-10% |

| Power capacity | 15 KVA | |

| Machine dimensions | Machine height | 2,600(102.36) mm(inch) |

| Floor space [with control unit door opened] | 2,421(95.32)*1,650(64.96) mm(inch) | |

| Weight(including control unit and splash guard) | 3,500(7716) kg(lbs) | |

| Accuracy | Positioning accuracy | 0.005/300(0.0002 / 11.8) mm(inch) |

| Repeat positioning accuracy | +/-0.003(+/-0.00012) mm(inch) | |

2. Features

Larger work table improve machining ability.

Greatly reduced tool change time to achieve high productivity (Cut to Cut 1.3s)

Optimized the shape of the structure and arrangement of ribs to enhance machine rigidity, leading to improved cutting performance.

3. Standard accessories

(1) Work Light

(2) Signal Light

(3) Foundation Plates and Bolts

(4) 14-Tool Changer

(5) Cooling System

(6) Automatic Lubricating Device

(7) Splash-proof Metal Sheet

(8) Toolkit

(9) Bed Shower

(10) Safety Door Lock

(11) Hand-operated MPG

(12) Special Technical Documents

4. Optional Accessories

(1) Hydraulic Unit

(2) NC rotary table

(3) NC Slant Rotary Worktable

(4) Hand-operated MPG

(5) Transformer (Unnecessary for SIEMENS System)

(6) Air-conditioner for Electrical Cabinet

(7) Higher Column

(8) Spraying Water from Spindle Center

(9) Spindle Cooling System

5. Part of applications

(1) auto industry

(2) medical industry

(3) military industry

(4) IT industry

(5) others

6. Factory Advantages

(1) Annual production: 2000sets.

(2) Spindle and tool changer are produced independently, based on German technology.

(3) R&D center: founded in 2006.

(4) Patents and honors: more than 60 certificates.

(5) Sales network: 9 regions, 23 offices in China; 5 branches around the world.

(6) 3 part warehouse: 1 in Shanghai, 1 in Changzhou and 1 at oveseas.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.